Showroom

From oil, Diesel mechanical to Digital turbine, buy from us different types of Electromagnetic Flowmeter. These flow meters are ideal for liquids only. The measuring instrument without any moving parts is not affected by the contaminants and deposits.

By from us rotameter to measure fluids volumetric flow rate enclosed in a tube. The flow rate is measured by just gravity and properties of fluid. Different models of this simple device is available for purchase.

Level indicator is a measuring device that indicate the accurate level of fluid in any container, from drum to tank. This indicator can be incorporated into the existing system with ease.

Customers can trust us for buying different types of level switches, such as conductivity type and displacer type. Based on the installation type, we supply both, top mounted and side mounted level switches.

Sight glass indicator is a level gauge which can indicate the level of the liquid, whether water, oil or any other. This device is durable, efficient and environmentally safe.

Notable for its tube shaped appearance, U Tube Manometer is used for precise measurement of atmospheric pressure. This powder coated instrument consists of PVC scale with required marking, borosilicate glass made metering tube.

Orifice Flange Assembly is used during pipeline drilling work. This low maintenance flange assembly contains a set of flanges with weld neck design, jack screw, gaskets, bolt, orifice plate and plug.

Level Gauge is used for determining precise level of fluid stored inside process tank. This low maintenance measurement solution can be operated under different temperature, pressure and vibration prone working conditions.

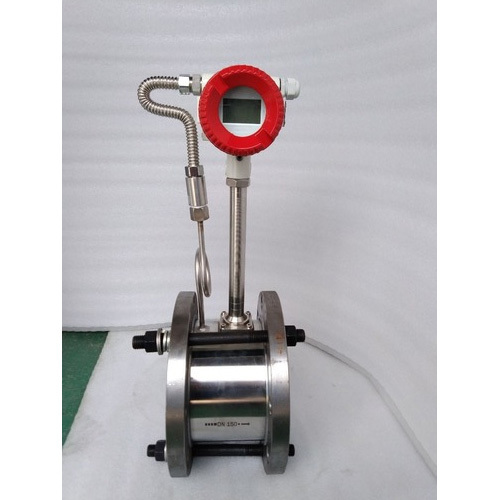

Turbine Flow Meter we deal in is used for the volumetric total flow as well as advanced flow rate measurement. It can work well with a simple working principle. It is suited for the applications that ask for highly accurate and exact measurements.

Full view sight glass is a sight flow indicator which can be monitored from 360-degree in order to keep a watch on material flowing through a line. Available in different sizes, this device is composed of different material for its end connections, lens, seal, studs, etc.

Hydrostatic level transmitter is a measuring device that works on a simple and reliable measuring method. It can be installed in vented vessels, tanks, enclosed vessels, open reservoirs, etc., with defined pressure connection, electrical connection and range of measurement.

The level of fluid can be detected by installing a cable float switch inside the tank or reservoir. This switch can be used in pools, factory vessels as well as wastewater treatment plant, as it can resist sewage, high viscosity fluid, acid and alkali.

Top Mounted Level Switches are needed for the control as well as monitoring of liquid levels in closed and open vessels. These switches allow for the maximum and minimum monitoring of fluid levels. These can work with safety and continuity.

We are engaged in providing FRP Molded Grating, which is made using fiber and polyester resin. These products are available in variable colors like green, yellow and red, as per the clients specifications. The products are well-known for their strength, safety, longer service life, light in weight and easy installation.

|

FLOWTECH MEASURING INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese