Tube Rotameters

Price 8100 INR/ Piece

Tube Rotameters Specification

- Sensor Type

- Mechanical Float

- Pressure Range

- Up to 10 Kg/cm (Higher on Request)

- Equipment Type

- Variable Area Flow Meter (Rotameter)

- Resolution

- Fine Graduation Markings for Precision Reading

- Temperature Range

- -20C to +120C Typical (Depends on Model)

- Capacity

- Up to 10,000 LPH (Liquids)

- Measurement Range

- Customizable per Application (Specify on Order)

- Flow Rate

- Directly Indicated on Tube Scale

- Connectivity Type

- Flange / Threaded / Hose Connections

- Humidity %

- Suitable for 0-100% RH (Non-condensing)

- Material

- Borosilicate Glass Tube; Wetted Parts in SS 304/316, PTFE or PVC as per application

- Power Supply

- Not Required (Operates Without Electrical Power)

- Power Consumption

- Zero

- Accuracy

- 2% of Full Scale

- Display Type

- Analog (Direct Tube Reading)

- Range

- 10 LPH to 10,000 LPH (liquids); 0.1 Nm/hr to 100 Nm/hr (gases)

- Installation

- Inline with Proper Verticality

- Glass Protection Cover

- Acrylic / Metallic Shield (Optional)

- Typical Applications

- Chemical, Pharma, Water Treatment, Laboratory, Gas Sampling, etc.

- Mounting Type

- Vertical Only

- Float Material

- SS 316 / PTFE / PVC / Glass

- Accessories

- Available with Flow Alarms & Limit Switches

- End Connections

- SS/PTFE Flanged, Threaded, Hose Nipples as Required

- Process Fluid Compatibility

- Suitable for Clear Liquids & Gases

- Calibration

- Factory Calibrated as per Fluid & Range

- Protection Class

- IP55 (Typical), Higher on Request

- Scale Units

- LPH, LPM, Nm³/hr, SCFM, Custom Units

- Standards Compliance

- Conforms to ISO 5167 / ISA RP16.6

- Maximum Viscosity

- Up to 1 cp (Higher on Special Design)

Tube Rotameters Trade Information

- Minimum Order Quantity

- 1 , , Piece

- FOB Port

- Vadodara

- Payment Terms

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Wooden Boxes

- Main Domestic Market

- Uttar Pradesh, Odisha, Chhattisgarh, Telangana, Dadra and Nagar Haveli, Uttarakhand, Sikkim, Meghalaya, West Bengal, Arunachal Pradesh, Central India, South India, Chandigarh, East India, Tamil Nadu, Mizoram, North India, Himachal Pradesh, Maharashtra, Delhi, Daman and Diu, Goa, Rajasthan, Kerala, Lakshadweep, Jharkhand, Madhya Pradesh, Karnataka, Tripura, Manipur, Andaman and Nicobar Islands, Jammu and Kashmir, Punjab, West India, Assam, Pondicherry, , Nagaland, Bihar, Andhra Pradesh, Gujarat, Haryana, All India

- Certifications

- ISO 9001, 14001, 18001

About Tube Rotameters

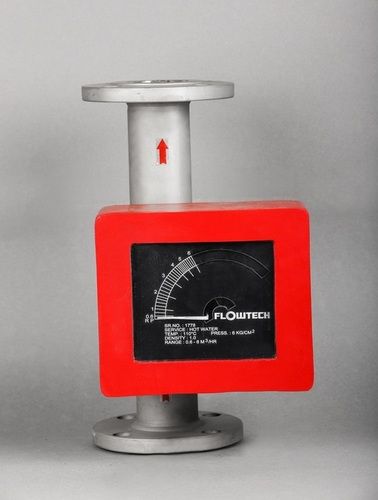

FLOWTECH Metal Tube Variable Area Flow Meters (Rotameters) are intended for application where high pressure, temperature OR corrosive conditions preclude the use of conventional glass tube. These are all Metal Variable Area type Flowmeter design to measure flow rate of liquids, gases & steam under critical conditions. It consists of a tapered metal tube, an indicating assembly and a float. A magnet encapsuled in float couples with rotating magnets connected to an indicating pointer, thus the movement of the float, is accurately indicated in terms of flowrate.

- Simplified piping and reduced space requirements.

- Permanent magnetic link between metering float and motion position transmitter.

- Precision swaged metering tube.

- Heavy duty welded float and guide construction.

- Guide cartridges easily removable for cleaning

- Provide with Electrical transmitter, flow indicator OR alarm.

FAQ for Tube Rotameters:

How does a tube rotameter work?

The Tube rotameter is functional on the principle of an adaptable area flow measurement.

What are some of the limitations of tube rotameters?

The device is accessible with several advantages, but it also has some limitations, which have been mentioned below;

- Pressure drop: Due to tube constriction, occurrence of pressure drop is possible.

- Limited turndown ratio: It has an inadequate turndown ratio in comparison to other flow meters.

- Sensitivity to alignment: It can be specially fitted in a specific orientation so as to ensure accurate readings. Variations in the installation position can affect the movement of float,

- The device is not apt to be used for the high-viscosity fluids.

What applications are tube rotameters commonly used for?

It has utility in various industries, including water treatment, chemical processing, pharmaceutical industry chemicals and solvents. This is also apt for measuring the flow rates of gases and liquids in the production processes of HVAC system, Laboratory research and Oil and gas industry.

Precise Flow Measurement Made Simple

Tube Rotameters offer a reliable and user-friendly way to measure the flow rates of clear liquids and gases across a variety of sectors, including chemical processing, water treatment, pharmaceutical manufacturing, and research laboratories. Designed for vertical inline installation, each unit features fine graduation markings for easy readability and is calibrated for optimal performance according to user specifications. Optional accessories like alarms and covers further enhance safety and usability.

Robust Construction for Demanding Applications

Manufactured with materials such as borosilicate glass and options for wetted parts in SS 316, PTFE, or PVC, these rotameters withstand a wide range of process conditions, including temperatures from -20C to +120C and pressures up to 10 kg/cm. The protection class of IP55 ensures resistance against dust and water ingress, while optional shields and covers guard against mechanical damage, making them suitable for rigorous, industrial environments.

FAQs of Tube Rotameters:

Q: How is a Tube Rotameter installed and what mounting orientation is required?

A: Tube Rotameters must be installed vertically and inline with the process piping to ensure accurate measurement. This orientation allows the float to move freely according to flow rate, delivering reliable analog readings.Q: What end connection options are available for these rotameters?

A: Depending on your system requirements, Tube Rotameters can be fitted with SS or PTFE flanged ends, threaded ends, or hose nipples, supporting flexible integration into existing setups.Q: Where can these rotameters be used, and for which process fluids are they suitable?

A: These flow meters are suitable for clear liquids and gas streams in industries such as chemical, pharmaceutical, water treatment, and laboratory analysis. Material compatibility (SS 316, PTFE, PVC, Glass) ensures safe use with most non-corrosive and corrosive agents.Q: How does the rotameter indicate flow, and what units are displayed?

A: The rotameter displays flow directly on a calibrated tube scale with analog markings. Units such as LPH, LPM, Nm/hr, or SCFM are available, and custom engineering provides other measurement units upon order.Q: What benefits does a mechanical, non-powered rotameter offer over other types?

A: Because Tube Rotameters operate without electrical power, they provide zero energy consumption, ongoing reliability with minimal maintenance, and safe operation in both hazardous and remote locations.Q: When should calibration be specified, and how is accuracy ensured?

A: During ordering, specify your process fluid and required range to receive factory-calibrated units. Each meter is checked for 2% full-scale accuracy to match the intended application conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rotameters Category

Glass Tube Rota Meters

Price 4000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Borosilicate Glass Tube with Metal Fittings

Accuracy : 2% of Full Scale

Display Type : Other, Analog

Flow Rate : 10 to 100,000 LPH

Low Flow Glass Rotameter

Price 3600 INR / Piece

Minimum Order Quantity : 1 , , Piece

Material : Borosilicate Glass Tube with SS304/SS316/PTFE/Brass end fitting options

Accuracy : 2% of Full Scale

Display Type : Other, Direct Glass Tube Indication

Flow Rate : Low flow rates; precise as per model selection

Glass Rotameter

Price 4500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Borosilicate Glass Tube, SS 304/316, PTFE, or PVC End Fittings

Accuracy : 2% of Full Scale

Display Type : Other, Graduated Glass Tube

Flow Rate : As per Model, Up to 60,000 LPH

By Pass Rotameters

Price 9000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : SS316/SS304/P.P.

|

FLOWTECH MEASURING INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry