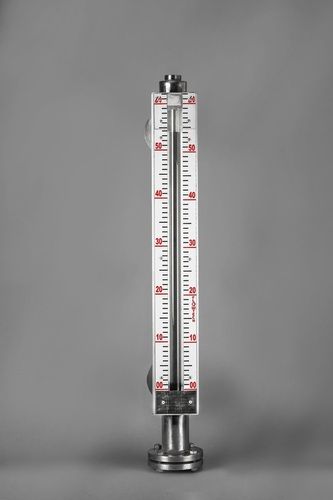

IBR Reflex Level Gauge

Price 8100 INR/ Piece

IBR Reflex Level Gauge Specification

- Display

- Full Visibility / Partial Visibility

- Usage

- level detection within a specific vessel, and the primary principle is based on the difference in refractive indices of vapor and liquid.

- Material

- Carbon Steel, S.S.304, S.S.304 (L), S.S.316, S.S.316 (L), P.P

- Size

- 15mm to 50mm Flanged

- Working Presssure

- 45 bar

- Height

- 400 Millimeter (mm)

- Product Type

- Reflex Level Gauge

- Weight

- 15 Kilograms (kg)

- Color

- Silver

- Length

- 400 Millimeter (mm)

- Accuracy

- 2 %

IBR Reflex Level Gauge Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Vadodara

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- WOODEN BOXES

- Main Domestic Market

- All India

- Certifications

- ISO 9001, 14001, OHSAS 18001

About IBR Reflex Level Gauge

FAQs of IBR Reflex Level Gauge:

Q: What is the accuracy of this level gauge?

A: The accuracy of the IBR Reflex Level Gauge is 2%.Q: What is the working pressure of this level gauge?

A: The working pressure of this level gauge is 45 bar.Q: What are the materials used to make this level gauge?

A: The IBR Reflex Level Gauge is made of high-quality materials such as Carbon Steel, S.S.304, S.S.304 (L), S.S.316, S.S.316 (L), and P.P.Q: What are the display options available for this level gauge?

A: The IBR Reflex Level Gauge comes in two display options: Full Visibility or Partial Visibility.Q: What is the weight of this level gauge?

A: The weight of this level gauge is 15 kilograms (kg).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Level Gauge Category

Side Mounted Magnetic Level Indicator With Transmitter

Price 16200 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Oil Refineries, Chemical Processing, Textile Industry, Water Engineering, Petro Chemical Plants

Usage : acid alkali solvent oil, vegetable Oil

Product Type : SIDE MOUNTED MAGNETIC LEVEL INDICATOR

Armoured Type Level Gauge

Price 8100 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Oil Refineries, Pharmaceutical Manufacture

Usage : Liquid and Gases

Product Type : Reflex Level Gauge

Side Mounted Magnetic Level Gauge

Price 7200 INR / Piece

Minimum Order Quantity : 1 , , Piece

Application : Oil Refineries, Petro Chemical Plants, Pharmaceutical Manufacture, Chemical Processing, Water Engineering, Textile Industry, Food And Beverages Industry

Accuracy : 0.5 %

Product Type : Magnetic Level Indicator

Bi - Color ROLLER Level Gauge

Price 8100 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Oil Refineries, Marine Engineering, Food And Beverages Industry, Textile Industry, Petro Chemical Plants, Pharmaceutical Manufacture, Chemical Processing, Mechanical Engineering, Water Engineering

Accuracy : 0.5 %

|

FLOWTECH MEASURING INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry