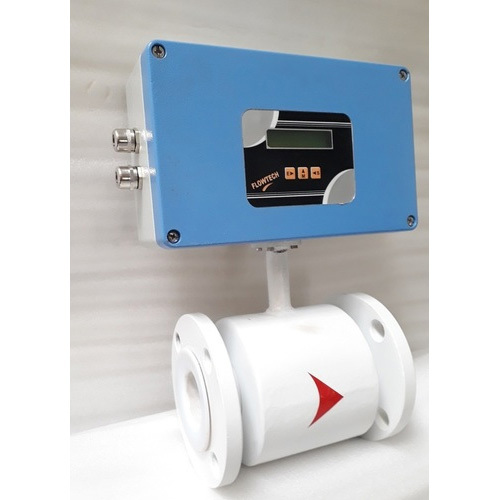

Turbine Flow Meter

Price 22000.0 INR/ Number

MOQ : 1 Piece

Turbine Flow Meter Specification

- Pressure Range

- 2.5MPa

- Temperature Range

- -20C to +80C Celsius (oC)

- Connectivity Type

- 4-20mA/RS485/Modbus

- Humidity %

- 95% RH (Non-condensing)

- Resolution

- 0.001 m3/h

- Measurement Range

- As per model specification

- Current Range

- 4-20mA Milliamperes (mA)

- Sensor Type

- Turbine Type

- Flow Rate

- 0.1 to 1500 m3/h

- Frequency

- Pulse out/Hz Hertz (HZ)

- Usage

- Industrial

- Material

- SS

- Power Supply

- 24V DC or 220V AC

- Power Consumption

- 5W Watt (W)

- Product Type

- Measuring Tool

- Accuracy

- 0.5% of reading %

- Display Type

- Digital Only

- Color

- Silver

- Range

- 0.1 to 1500 m3/h

Turbine Flow Meter Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Vadodara

- Payment Terms

- Paypal, Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- CORRUGATED BOXES

- Main Domestic Market

- Haryana, Nagaland, Meghalaya, Tamil Nadu, Telangana, Pondicherry, Uttar Pradesh, South India, Himachal Pradesh, Central India, Goa, West Bengal, Maharashtra, East India, Jharkhand, Kerala, Uttarakhand, West India, Rajasthan, Madhya Pradesh, Odisha, Bihar, Jammu and Kashmir, Gujarat, Daman and Diu, Arunachal Pradesh, Assam, Delhi, Lakshadweep, Tripura, Karnataka, Punjab, Chhattisgarh, Andhra Pradesh, North India, Sikkim, Chandigarh, Andaman and Nicobar Islands, Dadra and Nagar Haveli, Manipur, Mizoram, All India

- Certifications

- ISO 9001,14001,18001

About Turbine Flow Meter

FLOWTECH Measuring Instruments Private Limited the top manufacturer, exporter and supplier of Turbine Flow Meter since last 18 years and known for its high reliability and repeatable measurements under the most demanding conditions. This flow meter is employed for both lower viscosity gases and liquids. It is used for volumetric total flow and/or flow rate measurement and has a relatively simple theory of operation.

A turbine flow meter is constructed with rotor and blades which uses the mechanical energy of the fluid to rotate the rotor in the flow stream. Due to the standard magnetic tape the turbine experiences too much extra drag at low fluid velocities. These meters are in service worldwide as a reliable, cost-effective method for achieving accurate flow measurement.

Applications of Turbine Flow Meters:

- This flow meter is used in the monitoring of clean liquid flows in chemical, petroleum and water industries

- The custody transfer of hydrocarbons is one of the petroleum applications of this meter

- In the water industry, the meter is used for distribution systems between and within the water district

- It is also employed in industries like oil and gas, water and waste water, food and beverage, aerospace, gas utility, chemical, pharmaceutical, metals and mining and pulp and paper

Advantages of Turbine Flow Meters:

- Simple to use and well understood advanced technology

- Suitable for gases and liquids

- Great and accurate performance

- Wide operational uses

- Very cost effective

- Easy to install and easy to operate

FAQ - Turbine Flow Meter:

Is the Turbine Flow Meter simple to operate?

Yes, the Turbine Flow Meter is designed for simplicity and convenience of use. Its well-known design and technology make it user-friendly, making it simple for operators to install and maintain.

Is the Turbine Flow Meter capable of measuring both gases and liquids?

Yes, the Turbine Flow Meter is quite adaptable, measuring the flow of both gases and liquids. Because of its versatility, it is a helpful tool in a variety of sectors.

High-Precision Measurement

With an accuracy of 0.5% of reading and repeatability better than 0.05%, this turbine flow meter delivers consistently reliable measurements. The device is designed for industrial use cases, guaranteeing precise flow monitoring across varying conditions. Its stainless steel body ensures minimal maintenance while supporting a wide measurement range, from 0.1 to 1500 m/h, depending on the model.

Versatile Connectivity and Power Options

This flow meter supports multiple output signals, including Pulse, 4-20mA, and RS485/Modbus, making it seamless to integrate with diverse industrial control systems. Power flexibility is ensured with operation at either 24V DC or 220V AC and a low power consumption ( 5W), guaranteeing compatibility and energy efficiency across installations.

Rugged Design for Industrial Environments

Engineered with IP65 ingress protection and constructed from stainless steel, this instrument withstands challenging industrial conditions. Its wide operating range (-20C to +80C temperature, 95% RH humidity, and 2.5MPa pressure) allows it to perform efficiently in various harsh settings, ensuring reliability and longevity.

FAQs of Turbine Flow Meter:

Q: How is the turbine flow meter installed in an industrial piping system?

A: The turbine flow meter is designed for inline mounting and can be installed using either flanged or threaded process connections, depending on your piping specifications. Ensure correct alignment and secure placement at the recommended pipe size (DN4 to DN200) for optimal accuracy and performance.Q: What output signals does this turbine flow meter support for integration?

A: This flow meter provides multiple output signals, including Pulse, 4-20mA current, and RS485 with Modbus protocol, making it compatible with various data acquisition and industrial automation systems.Q: When should I use a turbine flow meter over other flow meters for my application?

A: Turbine flow meters are ideal when high-precision liquid flow measurement and fast response time are needed in clean, non-viscous fluid processes. They are best suited for industrial applications where repeatability and reliability are critical.Q: Where can the turbine flow meter be deployed?

A: This device can be deployed in a variety of industrial environments due to its robust stainless steel construction and IP65 ingress protection. Install it wherever precise liquid flow monitoring is required, provided the media and conditions are compatible with the meters temperature, humidity, and pressure ratings.Q: What is the process for connecting the flow meter to a monitoring or control system?

A: After mechanical installation, connect the signal wiring to your control system using the appropriate interface (Pulse, 4-20mA, or RS485/Modbus). Then, supply power via 24V DC or 220V AC as per your facilitys capabilities. Ensure all connections are secure and follow the provided wiring diagram for correct configuration.Q: How can users benefit from using this turbine flow meter?

A: Users benefit from precise and reliable flow monitoring, with high accuracy and repeatability. The digital display provides clear readings, while versatile output signals and robust construction reduce maintenance needs and ensure seamless integration into existing automation systems.Q: What are the recommended usage conditions for this turbine flow meter?

A: Operate the turbine flow meter within a temperature range of -20C to +80C, humidity up to 95% RH (non-condensing), and pressure up to 2.5MPa to maintain accurate and reliable performance as specified.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Turbine Flow Meter Category

Digital Turbine Flow Meter

Price 22500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Usage : Industrial

Display Type : Digital Only

Accuracy : +/ 0.5 %

|

FLOWTECH MEASURING INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry