Float and Board Type Level Indicator

Price 6000 INR/ Number

Float and Board Type Level Indicator Specification

- Display

- Board Type (Large Scale, Graduated)

- Measuring Range

- Up to 15 Meters

- Protection Level

- IP65

- Sensor Type

- Float

- Product Type

- Level Indicator

- Operating Temperature

- 50 Celsius (oC)

- Working Temperature

- 100 Celsius (oC)

- Input

- None (Mechanical)

- Pressure Type

- Atmospheric

- Warranty

- 12

- Connectivity Type

- Mechanical Linkage

- Application

- Industrial & Chemical Process Tanks

- Output

- Visual Display

- Features

- Corrosion Resistant, Sturdy Float, Weatherproof Construction

- Service Life

- >5 Years

- Dimension (L*W*H)

- Depends on tank height (Custom)

- Diameter

- Customizable as per tank

- IP Rating

- IP65

- Installation Type

- Top Mounting

- Material of Construction

- SS304/SS316/PP/PVC

- Float Material

- SS316 or Polypropylene

- Weight

- Varies based on size

- Accuracy

- ±10 mm

- Graduation Units

- Liter/Meter or Custom

- Mounting Type

- Flanged or Threaded

- Surface Finish

- Powder Coated/Polished

- Ambient Temperature

- -10°C to +70°C

- Switch Type

- None (Indicator Only)

- Tank Type Compatibility

- Vertical or Horizontal Tanks

- Usage & Applications

- Liquid Level Indication in Storage Tanks

Float and Board Type Level Indicator Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- Vadodara

- Payment Terms

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C)

- Supply Ability

- 500 Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- WOODEN BOXES

- Main Domestic Market

- All India

- Certifications

- ISO 9001, 14001, 18001

About Float and Board Type Level Indicator

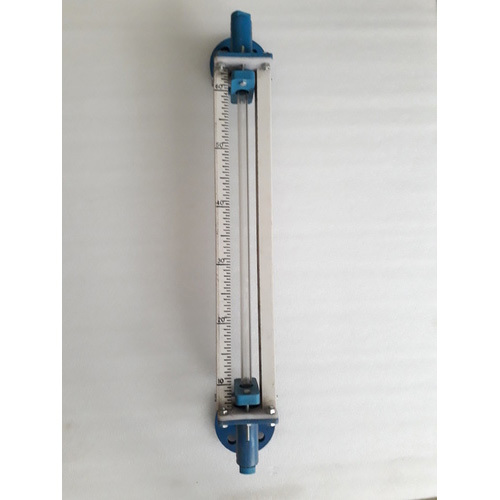

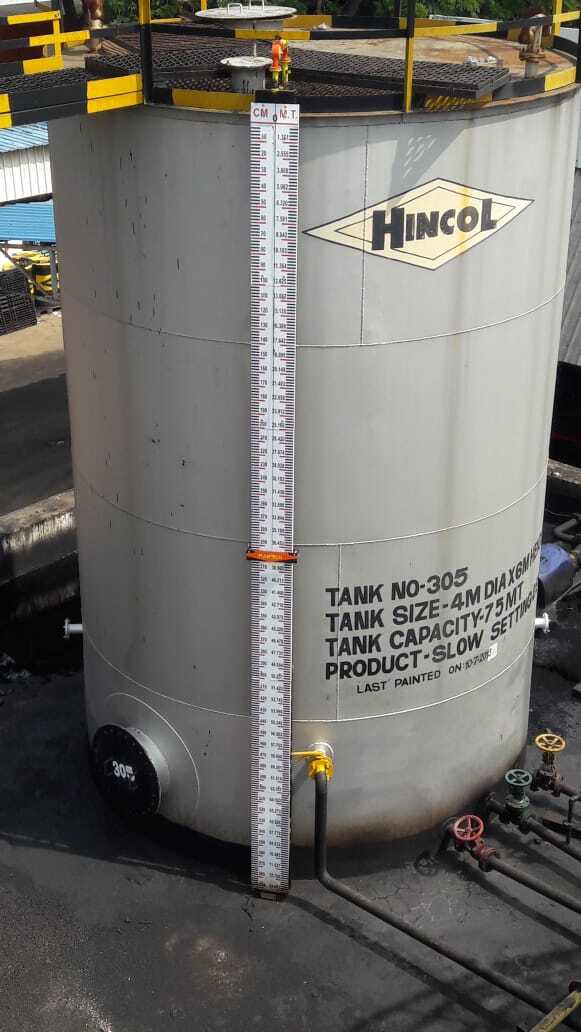

Flowtech offer Float & Board Type Tank Level gauge (indicator) suitable for large non - pressurized liquid storage tanks / vessels. This gauge is also applicable to cone roof, float roof, floating roof, under grand tanks etc. The Specific Gravity of the fluid should be more than 0.6(Free Flow) This level gauge wonks on the principle of buoyancy. The whole unit consist of two type of parts. Viz wetted parts & Non-wetted parts. Wetted parts are those which comes in contact with the liquid e.g. Float anchor plan float guide wire etc while. Non-wetted parts are the one which do not come in contact with the liquid e.g. Float wire, Mountain Breakers indicator pulley, pulley hosing scale, indicator etc.

The Float is available in different material S.S.304/S.S.316/P.P./ptfe etc. In this level gauge, the float is design as per the specific gravity of the liquid, floating on the liquid levels. This float connected to a pointer through Rope via a Sets of Pulleys, The pointer slides over CM marked Board, Installed Parallel to the tank. For more than 5 metre height of the tank we provide two guide wires firmly anchored to the tank bottom. So that horizontal movement of the float is restricted.

Design Features of Float and Board Type Level Indicator:

Flowtech also offers vapour Seal Type float & Board type level Gauge which is generally used for tanks having corrosive fumes / vapours OR N2 [Nitrogen] Purging tanks. In this level gauge the float is connected to a magnetized counter weight moving in a sealed S.S. pipe & which drives a follower magnetized bi - colour capsule inside a glass tube to indicate liquid level.

Performance:

Float Inside the tank raises and deals with the level of fluid this makes the pointer move on the scale indicating level inside the tank. In this level gauge, when tank is full the pointer is at bottom position on board and when tank is empty, the pointer will be at top position.

Float and Board Type Level Indicator Features:

- It is a simple, low-cost, and dependable level gauge that may be used in a variety of applications.

- The gauges wetted sections are available in SS304, SS316, or PP, giving versatility for various working situations.

- It is simple to install on existing tanks and allows for quick level monitoring.

- With the use of PVC rollers, the indicator runs smoothly across the gauge board, giving accurate and exact level readings.

- For best performance, it may be employed in situations involving volatile liquids or inert gas blanketing by utilizing a liquid seal assembly.

- The level gauge has big numbers that are clearly visible and legible from a distance, making it more user-friendly.

- It provides an easy installation and commissioning process, saving time and effort during setup.

Materials of Construction:

- Float S.S.316 / S.S.304 / Poly Propylene

- Float Wire & Float Guide Wire S.S.316 / Poly Propylene

- Pulley & Pulley Pin M.S. / S.S.304

- Pulley Housing Aluminium / S.S.304 / S.S.316 die Cast weather Proof Enclosure of Weather Proof

- Board (Scale) Aluminium with Powder Coated having 150 mm Width & White Back Ground & Black writing at every 10CM and Red Marking at Every Meter.

- Anchor Plate M.S / S.S.304 / S.S.316

- Scale Bracket (T) M.S. / S.S.304

- Pointer M.S / S.S.304 with PP Roller for Frictionless Sliding On Board.

- Available From 1 Metre to 30 Metre.

FAQ for Float and Board Type Level Indicator:

What applications are this Level Gauge employed for?

The Simple, Low-Cost, and Reliable Level Gauge may be utilized in a variety of applications that require level monitoring, such as tanks in service that require accurate level measurement.

Is it simple to install and maintain this special Level Gauge?

Yes, the Simple, Low-Cost, and Reliable Level Gauge is easy to install and commission. It also requires minimal maintenance, certainly making it a convenient choice for level measurement needs.

Reliable Level Measurement

Ensure accurate and continuous liquid level monitoring in storage tanks with our mechanical Float and Board Type Level Indicator. Designed for industrial reliability, it provides visual indication without the need for electrical connectivity, suitable for environments with atmospheric pressure and harsh process conditions.

Custom-Built for Varied Applications

You can tailor the level indicator to specific tank sizes, heights, and materials, making it ideal for diverse chemical and industrial applications. Its compatibility with both vertical and horizontal tanks ensures flexible installation, while the large graduated board helps in quick and easy visual assessment.

Durable and Resistant Design

Constructed from corrosion-resistant materials such as SS304, SS316, polypropylene, or PVC, the indicator withstands aggressive chemicals and atmospheric conditions. Powder-coated or polished surface finishes add further longevity, making it suitable for demanding industrial environments.

FAQs of Float and Board Type Level Indicator:

Q: How is the Float and Board Type Level Indicator installed on an industrial tank?

A: The level indicator is installed via top mounting, using either a flanged or threaded connection, depending on the tanks design. This setup allows for easy access and compatibility with both vertical and horizontal storage tanks.Q: What types of liquids can this indicator measure efficiently?

A: It is suitable for a wide range of liquids in industrial and chemical process tanks due to its sturdy float and corrosion-resistant construction. Common applications include water, chemicals, and process fluids in atmospheric pressure conditions.Q: When should the level indicator be used for maximum effectiveness?

A: The indicator is best used in scenarios where continuous, reliable, and visual liquid level monitoring is necessary, especially in environments without electrical supply or where mechanical solutions are favored for safety or resistance to harsh conditions.Q: Where is this product typically installed?

A: It is commonly installed on storage tanks in process industries and chemical plants, including outdoor and indoor settings. Its weatherproof and IP65-rated construction makes it suitable for varied environmental conditions.Q: What is the installation process for this level indicator?

A: Installation involves mounting the device on the tanks top via the supplied flange or threaded connector, suspending the float inside the tank. The mechanical linkage relays the float position to the graduated board for visual indication.Q: How does using this indicator benefit industrial facilities?

A: Using this indicator ensures safe, reliable monitoring of liquid levels without reliance on electricity, minimizing maintenance and providing a durable solution with a service life exceeding five years. Its mechanical linkage and weatherproof design further reduce operational risks.Q: What customization options are available for different tank applications?

A: Customizable features include diameter, measuring range up to 15 meters, display graduation units (liter, meter, or custom), material of construction (SS304, SS316, PP, or PVC), float material, and display board size to suit specific tank dimensions and process requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Level Indicator Category

Float And Board Level Indicator

Price 8100 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Industrial tanks, water treatment plants, oil storage tanks

Working Temperature : Up to 65C

Pressure Type : Atmospheric

Operating Temperature : 10C to +65C

Bicolor Roller Type Level Indicator

Price 8100 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Water,Chemical

Working Temperature : 150 Celsius (oC)

Pressure Type : 15

Operating Temperature : 150 Celsius (oC)

Fuel Tank level indicators

Price 6300 INR / Piece

Minimum Order Quantity : 1 Piece

Application : WATER, BOREWELL WATER, CEMICAL, ALCOHOL

Working Temperature : 100 Celsius (oC)

Side Mounted Tubular Level Indicator

Price 2700 INR / Piece

Minimum Order Quantity : 1 , , Piece

Application : Water,Liquid, Gas, DMA, TEA.

Working Temperature : 150 Celsius (oC)

Pressure Type : 10 kg/cm2

Operating Temperature : 150 Celsius (oC)

|

FLOWTECH MEASURING INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry