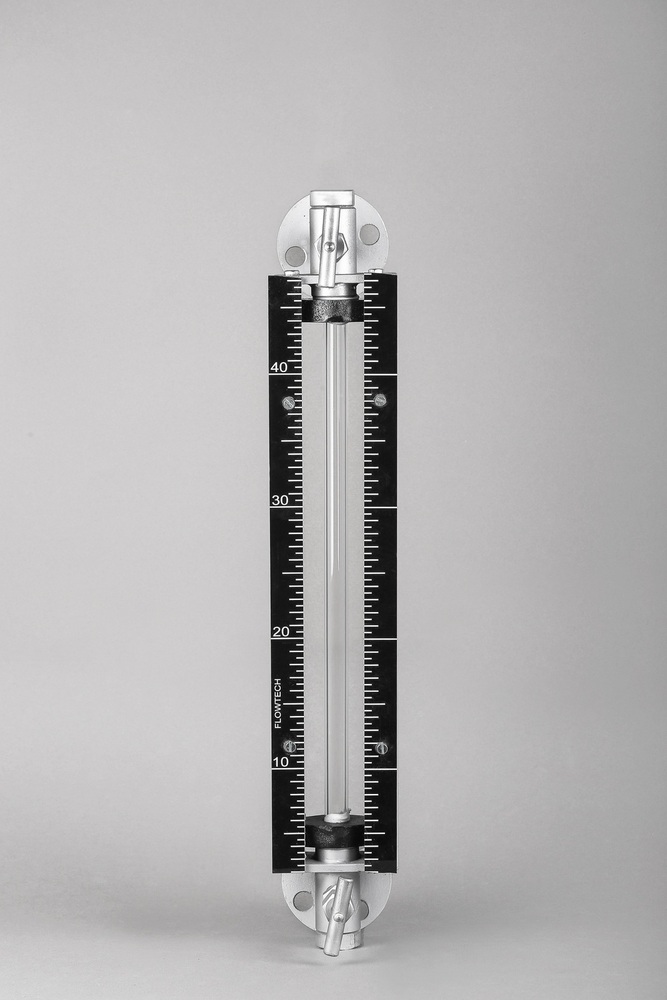

Armoured Type Level Gauge

Price 8100 INR/ Piece

Armoured Type Level Gauge Specification

- Outer Size

- 15mm to 65mm Flanged

- Measuring Range

- 3000 Celsius (oC)

- Usage

- Liquid and Gases

- Size

- 15mm to 65mm Flanged

- Product Type

- Reflex Level Gauge

- Application

- Oil Refineries, Pharmaceutical Manufacture

Armoured Type Level Gauge Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Vadodara

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Wooden Cage with Thermocol sheet packed

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Asia, Central America, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001, ISO 14001, OHSAS 18001

About Armoured Type Level Gauge

Armoured Type Level Gauge Features:

- Highly transparent borosilicate glass and acrylic body that gives high clarity.

- The sturdy armored body adds extra strength and rigidity.

- Secured attachment to make tight leakproof connections.

- High compatibility with corrosive and non-corrosive flow systems.

Armoured Type Level Gauge Working Principle:

Application of Armoured Type Level Gauge:

- Reflex glass level gauges can be used in most of the cases and offer great advantages in terms of: low initial cost, low operating cost, easy level reading. Reflex level gauges cannot be used in certain cases as for example:

- when the separation level between two liquids has to be read (interface)

- when besides the level indication, the observation of the liquid colour is required

- when the process fluid is high-pressure water steam, since in this case the glass must be protected from the solvent action of the boiler water by using mica shields

- when the process fluid is such that can corrode the glass (e.g. high temperature alkaline solutions or hydrofluoric acid), since ica shields or Polytrifluorochloroethylene shields must be used to protect the glass

Armoured Type Level Gauge - FAQ:

FAQs of Armoured Type Level Gauge:

Q: What is the measuring range of the Armoured Type Level Gauge?

A: The measuring range of this gauge is up to 3000 Celsius.Q: What industries can use the Armoured Type Level Gauge?

A: This gauge is suitable for use in oil refineries, pharmaceutical manufacturing, and other industries that require accurate level measurements.Q: What sizes does the Armoured Type Level Gauge come in?

A: This gauge comes in sizes ranging from 15mm to 65mm flanged.Q: Is the Armoured Type Level Gauge durable?

A: Yes, this gauge is constructed with sturdy materials to ensure longevity and durability.Q: Is the display on the Armoured Type Level Gauge easy to read?

A: Yes, the display on this gauge is designed for quick and easy monitoring of levels.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Level Gauge Category

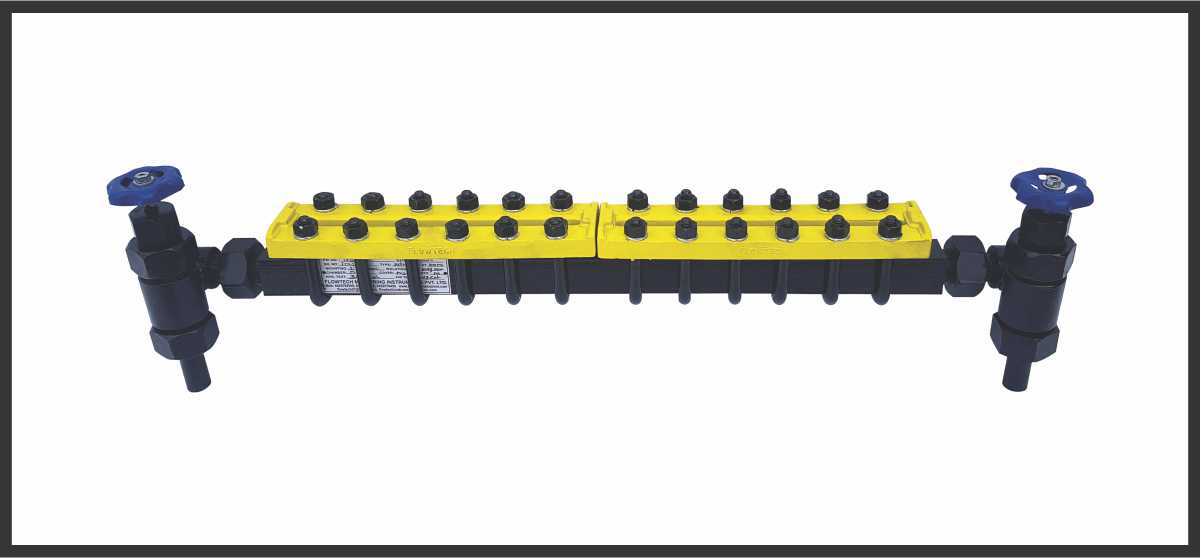

Reflex Level Gauges

Price 10800.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Carbon Steel, S.S.304, S.S.304 (L), S.S.316, S.S.316 (L), P.P

Accuracy : 99.8 %

Display : Full Visibility / Partial Visibility

Size : 15mm to 65mm Flanged

IBR Reflex Level Gauge

Price 8100 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Carbon Steel, S.S.304, S.S.304 (L), S.S.316, S.S.316 (L), P.P

Accuracy : 2 %

Display : Full Visibility / Partial Visibility

Size : CC Distance : 300, 320, 400, 450, 500 MM

Side Mounted Magnetic Level Indicator With Transmitter

Price 16200 INR / Piece

Minimum Order Quantity : 1 Piece

Material : SS 304, SS 304L, SS 316 SS 316L, PP, PVDF, SS.316 with PTFE Coated

Size : 300 to 6000mm

Tubular Glass Level Gauge

Price 2520.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Accuracy : 0.5 %

Display : Analog

|

FLOWTECH MEASURING INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry