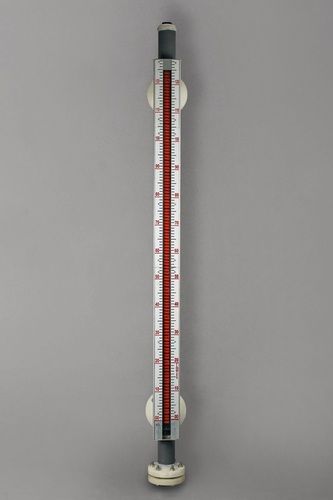

Magnetic Level Indicator

Price 7200 INR/ Piece

Magnetic Level Indicator Specification

- Phase

- Single Phase (if electrical option attached)

- Installation Type

- Side-mounted / Top-mounted

- Protection Level

- IP65 or higher (with enclosure)

- Sensor Type

- Float with Magnetic Coupling

- Features

- Simple operation, No power required for indication, Rugged construction, Suitable for corrosive fluids

- Connectivity Type

- Spare terminals for switches

- Mounting Type

- Flanged / Threaded

- Output

- Mechanical Display, Optional Electrical Switches

- IP Rating

- IP65 (Standard)

- Switch Type

- Magnetic Reed Switch (Optional)

- Display

- Magnetic Shuttle/Follower with Indicating Scale

- Usage & Applications

- Chemical, Petrochemical, Water Treatment, Process Industries

- Pole Type

- Single Pole (Switch)

- Measuring Range

- Customizable (typically 150 mm to 5000 mm)

- Product Type

- Magnetic Level Indicator

- Operating Temperature

- -20C to 120C

- Working Temperature

- -20C to 120C

- Pressure Type

- Up to 10 kg/cm

- Diameter

- 19 mm to 55 mm (Float Diameter)

- Application

- Level Measurement in Tanks and Vessels

- Supply Voltage

- Not Required (Mechanical Display), 24V DC (for optional switches)

- Accuracy

- 10 mm

- Dimension (L*W*H)

- Depends on Measuring Range and Model

- Weight

- Varies as per Construction & Range

- Optional Accessories

- High/Low Level Alarm Switch, Remote Transmitter

- Process Connection Size

- Custom as per application (usually 1 to 2 Flanged or Threaded)

- Material of Construction

- SS304/SS316/PP/PTFE

- Scale Material

- Anodized Aluminum or Stainless Steel

- Fluid Compatibility

- Stainless Steel, PP, PTFE wetted parts available

- Density Range

- Suitable for liquids with density above 0.6 kg/l

- Float Material

- 316 SS / Polypropylene / PTFE

- Max Length

- Up to 5 meters or as required

Magnetic Level Indicator Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Vadodara

- Payment Terms

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Magnetic Level Indicator

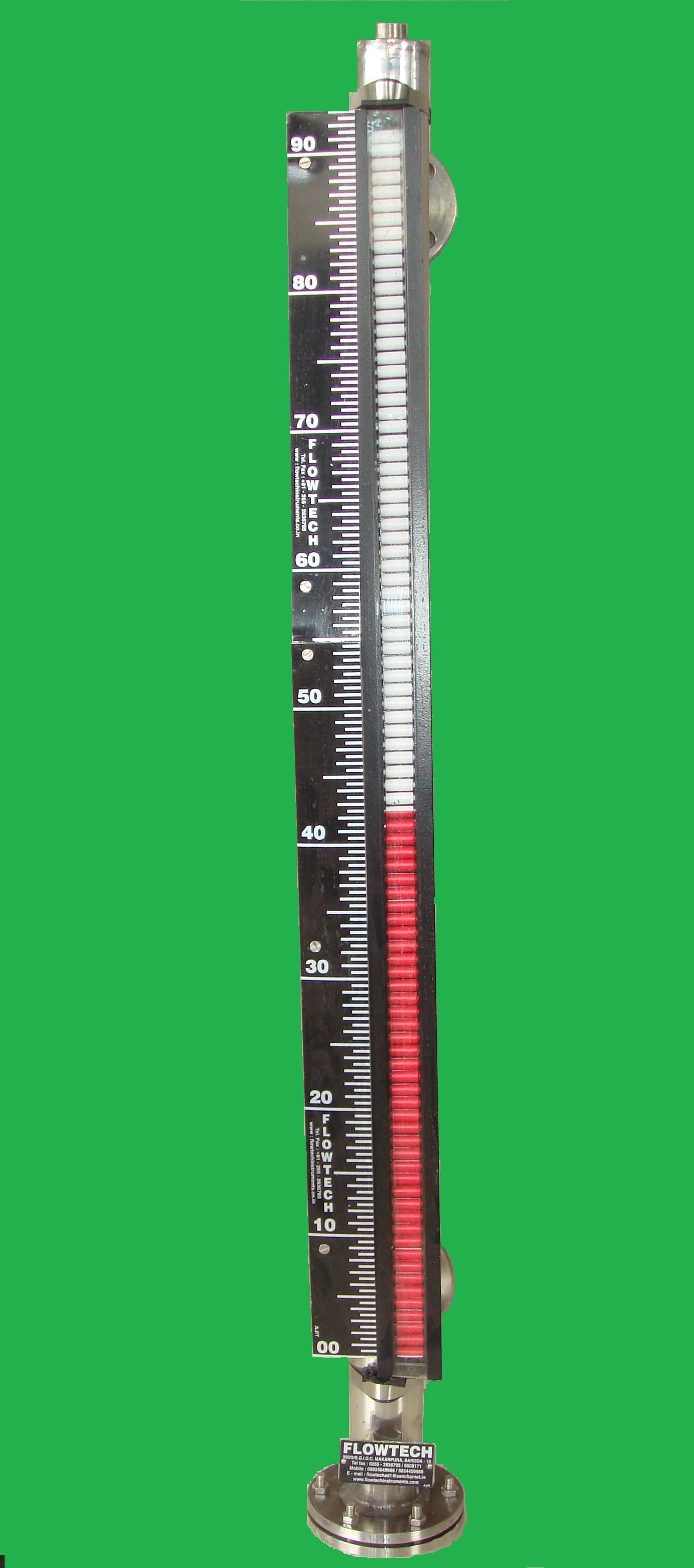

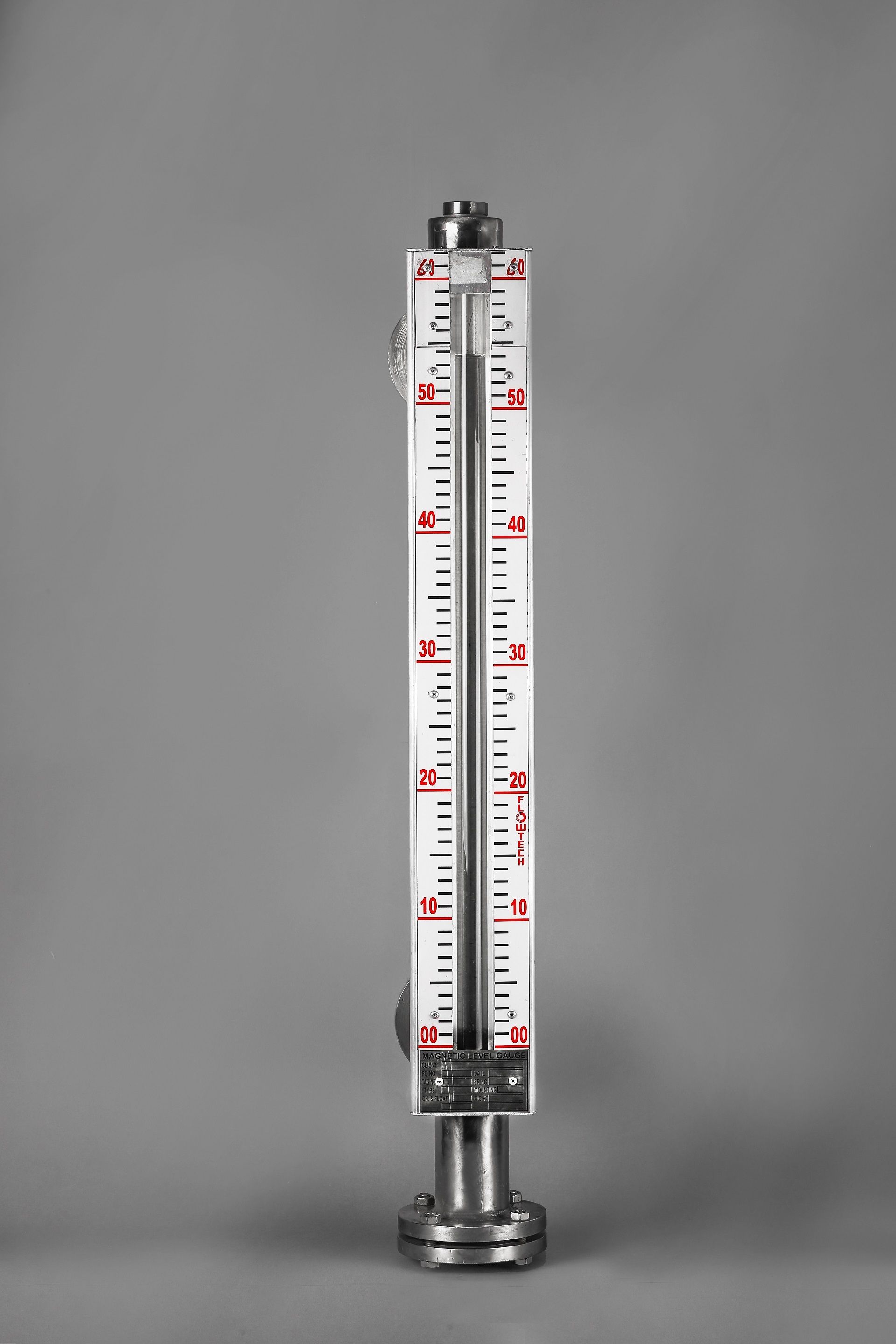

FLOWTECH make Magnetic Level Gauge provides clear, high clarity indication of liquid level. Magnetic Level Gauges are principally designed as an alternative to glass level gauges. Flowtech Instruments Services offers Magnetic Level Gauges in top-bottom, top and side mounted construction with two types of indicator system i.e. Capsule and Bi-colour Rollers. Magnetic Level Gauge is consists of three major components: Float Chamber, Float and Indicator System. Magnetic Level Gauge operates on the principle of magnetic field coupling to provide fluid level information. Float chamber is typically constructed with non magnetic pipe having process connections that matches to the vessel connections. Float size and weight is determined by the process fluid, pressure, temperature and the specific gravity of the process fluid. Float contains magnets to provide 360o magnetic flux field.

FLOWTECH maketop Mounted Level Indicator Substitute to the dip sticks method (for Horizontal & Vertical Tanks.) Corrosive acids like Sulphuric, Nitric, Chlorosulphuric, Acetic Acids, Solvents like Benzene, Acetone, Tol-uene, OR any Organic Liquids like Butadine, Vinyl chloride. NO maintenance and NO motive power require. Simple Non Magnetic can offer where bi-colour PVC capsules mounted on the float moves in glass tube externally.

Design Features of Magnetic Level Indicator:

Indicator system is consists of bi-colour rollers equipped with magnets mounted on rail inside the housing. As the level starts rising or falling magnetic float also travels with liquid level in non magnetic chamber. The magnetic interaction between magnets in float and bi-colour rollers causes each roller to rotate 180o. We are providing high & low Level Switch adjustable.

Capsule Design:

Indicator system consists of bi-colour capsule which moves in glass tube inside the housing. As the level stars rising or falling magnetic float also travels with liquid level in non magnetic chamber. The magnetic interaction between magnets in float and capsule causes capsule to travel along with magnetic float. We are providing high & low Level Switch adjustable.

FAQ for Magnetic Level Indicator:

What are the primary parts of a Magnetic Level Gauge?

A Magnetic Level Gauge is made up of three basic parts: a float chamber, a float, and an indicator system. The float chamber is made using a nonmagnetic material.

What is the operation of a Magnetic Level Gauge?

A Magnetic Level Gauge works on the basis of magnetic field coupling. The magnetic interaction of the floats magnets and the indication system delivers fluid level information.

What are the benefits of a Top Mounted Level Indicator?

- It does not need for maintenance or an extra power source.

- It provides a simple and dependable level measurement solution.

- It essentially features adjustable high and low-level controls.

Superior Material Selection for Fluid Compatibility

Tailored construction options allow selection of SS304/SS316, PP, or PTFE materials for both wetted and float components, ensuring compatibility with various fluids, including corrosive and aggressive chemicals. Scale materials are available in anodized aluminum or stainless steel for enhanced resistance and longevity in diverse operating environments.

Flexible Installation and Measurement Solutions

Customizable measuring ranges (150 mm to 5000 mm), float diameters, and process connection sizes (typically 1 to 2, flanged or threaded) enable precise measurement tailored to application requirements. Side-mounted and top-mounted installation types, coupled with IP65 protection, guarantee reliable performance in industrial settings.

FAQs of Magnetic Level Indicator:

Q: How does the magnetic level indicator work for tank and vessel level measurement?

A: The indicator employs a float with magnetic coupling that tracks liquid level changes. As the liquid rises or falls, the magnetic float moves correspondingly, activating the mechanical display (magnetic shuttle/follower) on an external scale for clear level visualization.Q: What fluids can the device measure, considering material compatibility?

A: The indicator accommodates a wide range of fluids, including corrosive chemicals, thanks to wetted parts options in SS304, SS316, polypropylene, or PTFE. This versatility ensures compatibility with liquids having densities above 0.6 kg/l in chemical, petrochemical, and water treatment processes.Q: When is it advisable to use SS316, PP, or PTFE floats and wetted parts?

A: SS316 is recommended for most industrial liquids, including mildly corrosive fluids. PP and PTFE flotation and wetted parts are ideal for highly aggressive or corrosive chemicals, providing long-term durability and resistance in harsh environments.Q: Where can the magnetic level indicator be installed, and what mounting options are available?

A: The indicator can be installed on the side or top of tanks and vessels. Mounting options include flanged or threaded connections, customizable to application needs, ensuring secure and reliable operation in various industrial settings.Q: What is the process for integrating alarm switches or remote transmitters with the indicator?

A: Optional magnetic reed switches for high or low level alarms and remote transmitters can be installed through dedicated spare terminals. Electrical accessories operate on 24V DC, allowing integration into control systems for real-time monitoring, while mechanical display remains independent of power supply.Q: How easy is the indicator to use, and what are the benefits of mechanical display?

A: Operation is straightforward, requiring no external power for mechanical indication. The rugged construction minimizes maintenance, while the clear magnetic shuttle/follower scale enables quick and accurate visual inspection, enhancing safety and process reliability.Q: What industries benefit most from using this magnetic level indicator?

A: Industries such as chemical processing, petrochemical manufacturing, water treatment, and general process engineering benefit greatly, given the instruments compatibility with corrosive and diverse fluids, customizable ranges, and robust performance under challenging conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Level Indicator Category

Float and Board Type Level Indicator

Price 6000 INR / Number

Minimum Order Quantity : 1 Number

Working Temperature : 100 Celsius (oC)

Pressure Type : Atmospheric

Bicolor Roller Type Level Indicator

Price 8100 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Water,Chemical

Working Temperature : 150 Celsius (oC)

Pressure Type : 15

Fuel Tank level indicators

Price 6300 INR / Piece

Minimum Order Quantity : 1 Piece

Application : WATER, BOREWELL WATER, CEMICAL, ALCOHOL

Working Temperature : 100 Celsius (oC)

Roller Type Level Indicator

Price Range 3500.00 - 5000.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Application : Acids, NH3, CL2, LPG, PCL3, SO3, Liquid, Tea, Etc.

Working Temperature : 150 Celsius (oC)

Pressure Type : 15 kg/cm2

|

FLOWTECH MEASURING INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry