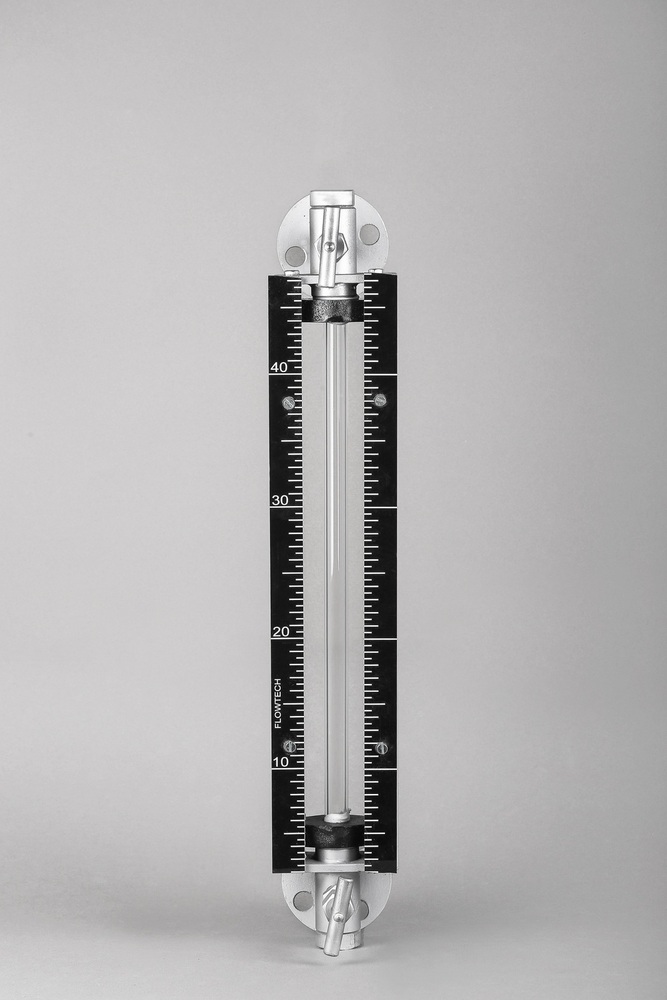

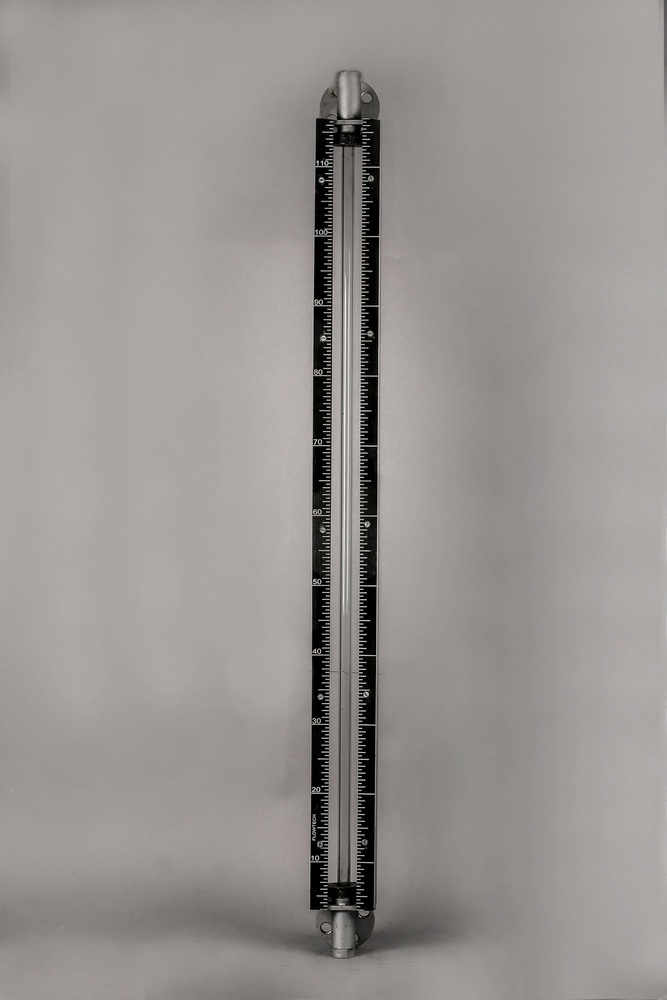

Tubular Glass Level Gauge

Price 2520.0 INR/ Unit

Tubular Glass Level Gauge Specification

- Measuring Range

- 0 - 40 Celsius (oC)

- Display

- Analog

- Material

- Stainless Steel

- Weight

- 2 Kilograms (kg)

- Application

- Oil Refineries

- Length

- 600 Millimeter (mm)

- Accuracy

- 0.5 %

Tubular Glass Level Gauge Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Vadodara

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C), Western Union, Cash Advance (CA), Delivery Point (DP), Paypal, Cash in Advance (CID), Letter of Credit (L/C), Cheque, Days after Acceptance (DA), Cash Against Delivery (CAD), Cash on Delivery (COD)

- Supply Ability

- 500 Units Per Month

- Delivery Time

- 4 Days

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- Pondicherry, Telangana, , South India, Uttar Pradesh, Daman and Diu, West Bengal, Maharashtra, Andaman and Nicobar Islands, Bihar, Lakshadweep, Karnataka, Chhattisgarh, Goa, Sikkim, Tripura, Himachal Pradesh, Jammu and Kashmir, Delhi, Arunachal Pradesh, Kerala, Gujarat, Mizoram, Rajasthan, Odisha, Madhya Pradesh, North India, Jharkhand, Central India, Meghalaya, Uttarakhand, East India, Chandigarh, Andhra Pradesh, Manipur, West India, Haryana, Assam, All India, Tamil Nadu, Nagaland, Punjab, Dadra and Nagar Haveli

About Tubular Glass Level Gauge

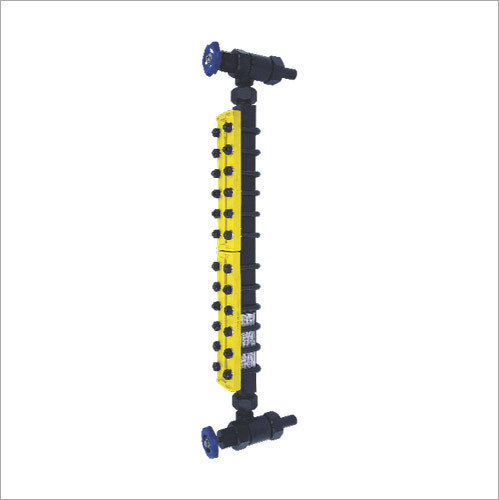

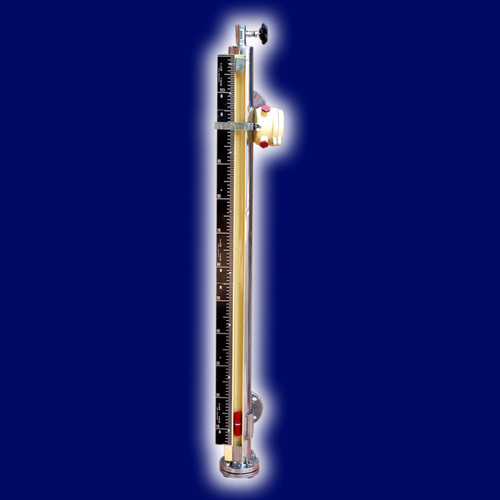

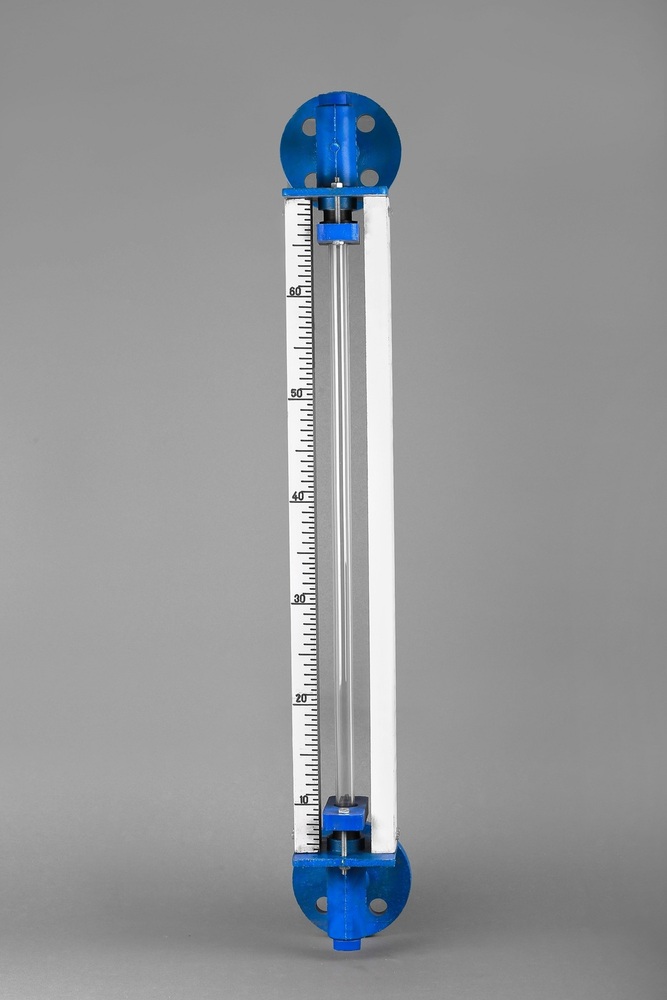

Flowtech Make Heavy Duty Tubular Liquid By Pass Level Indicator is a Simple & reliable device for direct reading in atmospheric or pressurized tank application. These indicators eliminates trouble giving threaded joints of conventional gauge glass cock as hazardous damage surrounding equipments & also endanger human life.- The top & bottom liquid Chamber of indicator is made of solid bar & Glass Tube (Borosilicate) is fully Protected by Box Section made out of 2 mm thick M.S. channel. The strength of the box is so good that even if a man stands on the indicator, supported at both ends, the tube remains intact.

- We are using 100% PTFE () rope as packing to ensure positive leak tightness for full vacuum as well as 6 Kg / Cm service pressure.

- As Compare to Reflex & Transparent type Level Gauge, this Tubular Level Indicator is light in weight.

- It is available in single length of 2000 mm C/C Distance. We can extend the length by coupling 2 or more through coupler.

- We are providing Air Vent Plug at top & drain plug at bottom for taking sample. We can also provide Inbuilt Isolation Valve on request.

- It is simple and reliable device for direct reading in atmospheric or pressurized (below 5 Kg/cm2) tank application.

- It Eliminates trouble giving threaded joints of Conventional Gauge Glass Cock as hazardous Chemicals Start leaking.

- Glass Tube (Borosilicate Boiler Quality) is fully protected by guard Rods or Box Section made of 'C' Channel.

- Offset Constructed Isolation Valve on request. The connection provided will be Flanged / Screwed / TC Joint.

Material of Construction:

- Scale: Aluminum / Acrylic / SSLiquid Chamber

- End Fitting: P.P / C.S. / S.S.304 / S.S.316 / MS with PP or Lined.

- Protection Guard: MS, SS-304, SS-316, PPTubular Level IndicatorSimple and reliable device for direct reading in atmospheric or below 5kg/cm pressurized tank.Bolted gland with ptfe packing ensures positive leak tightness for full vacuum as well as 10 kg/cm pressure.

- Available in Aluminum Acrylic, SS linearly calibrated scale.MOC; MS, SS-304, SS-316, P.P, MS WITH P.P /P.V.D.F./Lead lined.

- Offset constructed isolation valve on request.

Reliable Measurement for Refineries

Our Tubular Glass Level Gauge is engineered to deliver accurate and reliable readings, crucial for safe and efficient operation in oil refineries. The gauges analog display and robust stainless steel construction make it a trusted solution, even in challenging environments where durability and precision matter most.

Expert Manufacturing and Service

We operate as a manufacturer, supplier, exporter, producer, and service provider from India, delivering high-performance tubular glass level gauges. Our expertise spans product development, customization as per client needs, and comprehensive after-sales support to ensure seamless integration into existing refinery systems.

FAQs of Tubular Glass Level Gauge:

Q: How does the Tubular Glass Level Gauge function in oil refineries?

A: The Tubular Glass Level Gauge operates by enabling visual monitoring of liquid levels within storage tanks or pipelines. Its transparent glass tube shows the liquids height, allowing operators to accurately measure the contents and ensure safe process management.Q: What are the primary benefits of using a stainless steel construction for this gauge?

A: Stainless steel construction offers enhanced durability, corrosion resistance, and suitability for harsh industrial environments. This ensures reliable performance, longer lifespan, and reduced maintenance requirements when measuring liquids in oil refineries.Q: When should this level gauge be used for optimal results?

A: The gauge is best utilized whenever precise liquid level measurement is required in oil refineries, especially between 0 to 40C temperature ranges. Its high accuracy and robust build make it suitable for continuous monitoring during operational processes.Q: Where is the Tubular Glass Level Gauge installed within refinery facilities?

A: Typically, the gauge is installed on tanks, vessels, or pipelines where direct observation of liquid levels is necessary. Its design facilitates easy mounting and visibility in critical locations within oil refinery plants.Q: What is the usage process for reading the level on this analog display gauge?

A: Operators simply observe the height of the liquid through the glass tube and reference the analog scale provided. This direct visual method allows for quick and accurate readings without the need for electronic instrumentation.Q: How does the products accuracy benefit refinery operations?

A: With a measurement accuracy of 0.5%, operators receive precise data regarding liquid levels, minimizing risks of overfill or downtime. This accuracy is vital for efficient resource management and safety compliance in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Level Gauge Category

Reflex Level Gauges

Price 10800.0 INR / Piece

Minimum Order Quantity : 1 Piece

Accuracy : 99.8 %

Application : Oil Refineries, Marine Engineering, Food And Beverages Industry, Textile Industry, Petro Chemical Plants, Pharmaceutical Manufacture, Chemical Processing, Mechanical Engineering, Water Engineering, Pulp And Paper Industry, Nuclear Power Engineering

Size : 15mm to 65mm Flanged

Product Type : Reflex Level Gauge

Water Level Gauge

Price 8100 INR / Piece

Minimum Order Quantity : 1 Piece

Accuracy : 100 %

Application : Oil Refineries, Chemical Processing, Marine Engineering, Nuclear Power Engineering, Water Engineering, Petro Chemical Plants, Pharmaceutical Manufacture, Food And Beverages Industry

Size : Customizable

Product Type : Water Level Gauge

Armoured Type Level Gauge

Price 8100 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Oil Refineries, Pharmaceutical Manufacture

Size : 15mm to 65mm Flanged

Product Type : Reflex Level Gauge

Magnetic liquid level Gauge with Transmitter

Price 15000 INR / Piece

Minimum Order Quantity : 5 Pieces

Accuracy : +/1 %

Size : Standard

|

FLOWTECH MEASURING INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry