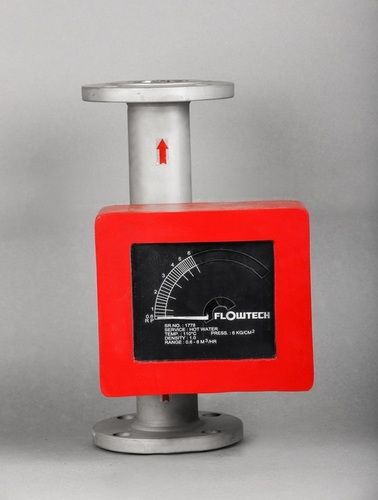

Variable Area Metal Tube Rotameter

Price 8100 INR/ Piece

Variable Area Metal Tube Rotameter Specification

- Usage

- Water

- Size

- 15 NB to 150 NB

- Material

- SS-304 & SS.316

- Product Type

- Magnetic Rotameter

- Accuracy

- 0.5 %

- Display Type

- Analog And Digital

- Color

- Red

- Range

- 150 LPH TO 100000 LPH

Variable Area Metal Tube Rotameter Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Mumbai

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 2 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Wooden Boxes

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- North India, Mizoram, Jharkhand, Delhi, Kerala, Bihar, Tripura, Telangana, Uttarakhand, Pondicherry, Jammu and Kashmir, Manipur, Dadra and Nagar Haveli, South India, Nagaland, Karnataka, Daman and Diu, Arunachal Pradesh, , Assam, Meghalaya, West Bengal, Tamil Nadu, West India, Andaman and Nicobar Islands, Madhya Pradesh, Chhattisgarh, Himachal Pradesh, Goa, Haryana, Central India, Lakshadweep, Maharashtra, Gujarat, Sikkim, Andhra Pradesh, Chandigarh, Odisha, Rajasthan, East India, Uttar Pradesh, Punjab, All India

- Certifications

- ISO 9001, 14001, 18001

About Variable Area Metal Tube Rotameter

Variable Area Flow Meter - Metal Tube Rotameter, is a crucial tool for monitoring and regulating the flow of different gases and liquids. Thisworks on the principle of variable area flow measurement, according to which the area between a float and a tapered metal tube is exactly proportional to the fluid flow rate. The float rises as the fluid moves through the tube, displaying the flow rate as a number on a scale. Variable Area Flow Meter - Metal Tube Rotameter is a popular option in sectors including chemical processing, pharmaceuticals, and manufacturing.

Features of Variable Area Metal Tube Rotameter:

- They represent a key advancement in industrial procedure.

- They are crucial tools for many different types of organizations.

- They rely on cutting-edge technology and electrical sensors to provide real-time measurements.

FAQ - Variable Area Metal Tube Rotameter:

What is a variable area flow meter?

The variable area flow meter has been made to measure the flow rate of several types of liquids or gases.

What are the benefits of using the Variable area flow meter metal tube rotameter?

- Simple and dependable design: It has no moving parts and there is a less risk of mechanical botch.

- Wide flow range: It can deal with a broad range of flow rates, from low to high, based on the size and design.

- Visual sign: The position of the float as well as conical tube shape bestow a visual indication of the flow rate, enabling simple and fast reading.

- Compatibility with assorted liquids and gases.

What are the limitations of Variable area flow meter metal tube rotameter?

- Pressure drop

- Limited accuracy

- Physical properties of fluid

FAQs of Variable Area Metal Tube Rotameter:

Q: What is the accuracy of this rotameter?

A: The Variable Area Metal Tube Rotameter has an accuracy of 0.5%.Q: What is the range of flow rates this rotameter can measure?

A: This rotameter can measure flow rates ranging from 150 LPH to 100000 LPH.Q: What materials is this rotameter made from?

A: This rotameter is made from durable SS-304 and SS.316 materials.Q: What display types does this rotameter feature?

A: This rotameter features both analog and digital display types.Q: What is the usage of this rotameter?

A: This rotameter is designed for measuring water flow rates.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Tube Rotameter Category

Digital Metal Tube Rotameter

Price 25200.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : SS.304 & SS.316

Accuracy : 0.5 %

Power Supply : 24V DC

Display Type : Digital Only

|

FLOWTECH MEASURING INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry