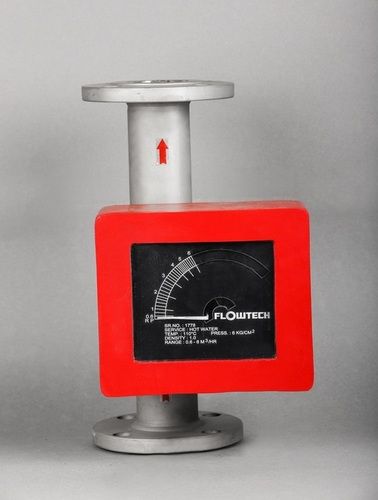

Low Flow Glass Rotameter

Price 3600 INR/ Piece

Low Flow Glass Rotameter Specification

- Resolution

- Fine scale graduations on tube

- Equipment Type

- Low Flow Glass Rotameter

- Flow Rate

- Low flow rates; precise as per model selection

- Temperature Range

- Up to 120C

- Measurement Range

- As per calibration; typically 10-1000 LPH

- Pressure Range

- Up to 10 kg/cm (150 psi)

- Humidity %

- Standard ambient operation

- Sensor Type

- Float-based visual flow measurement

- Connectivity Type

- Mechanical (Inline Flanged/Threaded)

- Capacity

- Low flow (as per specified model)

- Material

- Borosilicate Glass Tube with SS304/SS316/PTFE/Brass end fitting options

- Power Supply

- Not Required (Mechanical Operation)

- Accuracy

- 2% of Full Scale

- Display Type

- Direct Glass Tube Indication

- Range

- 10 to 1000 LPH (Liquid), 0.1 to 10 Nm/hr (Gas)

Low Flow Glass Rotameter Trade Information

- Minimum Order Quantity

- 1 , , Piece

- FOB Port

- Mumbai, Nhava Seva

- Supply Ability

- 25 Pieces Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Wooden Boxes

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001, 14001, 18001

About Low Flow Glass Rotameter

Low Flow Glass Rotameter Technical Detail:

- Accuracy :+/- 2% F.S.D.

- Temperature Ratings Maximum Operating Temperature rating is 121 o C for Gas services and 93 o C for Liquid services.

- Repeatability :0.5 %

- Connections :Flanged OR Screwed OR Triclover Joint OR Hose Nipple.

- Rangebility : 10:1

- Enclosure :IP 55 OR IP 65 on request.

- Scale length : 180-200 mm.

MATERIALSOF CONSTRUCTION:

- Tube :Borosilicate Glass

- Float :SS316, PTFE, Aluminium, and P.P.

- Pickings :Neoprene,PTFE, Silicon, Viton

- Frame &Cover : M.S.OR SS

- End Fitting :M.S.,C.S., SS304, SS316, CF-8M, CF8, C.I. PTFE Lined, SS PTFE Lined, PVC, others onrequest.

- Frame& Cover : M.S.OR SS

FAQs aboutLow Flow Glass Rotameter:

Can the Low Flow Glass Rotameter handle a variety of fluids?

Is the Low Flow Glass Rotameter safe to use?

What industries often employ Low Flow Glass Rotameters?

Versatile Installation Options

This rotameter supports both panel and field mounting in a vertical orientation and can be fitted with flanged or threaded ends. Its robust mechanical design facilitates inline installation for efficient monitoring in industrial applications, making it easy to integrate within existing process lines.

Superior Accuracy and Visibility

With scale markings engraved or printed directly on the glass tube, users benefit from fine resolution and direct tube indication. The float-based sensing mechanism delivers reliable visual readings, enhancing accuracy to within 2% of full scale for both liquids and gases.

Durability and Process Compatibility

Constructed from borosilicate glass with SS304, SS316, PTFE, or brass end fittings, the rotameter withstands pressures up to 10 kg/cm and temperatures up to 120C. Packing materials like PTFE or Viton further enable safe handling of compatible chemicals, air, water, and process gases.

FAQs of Low Flow Glass Rotameter:

Q: How is the Low Flow Glass Rotameter installed in a process system?

A: The rotameter is designed for vertical mounting, either on a panel or directly in the field. It supports both flanged and threaded connections (BSP or NPT) ranging from 1/4 to 1, making integration with process pipelines or equipment straightforward.Q: What fluids and gases can be measured with this rotameter?

A: This device is compatible with water, air, a variety of industrial gases, and chemicals that do not react with borosilicate glass and selected end fitting/passing materials (SS304/SS316/PTFE/Brass). Please consult with your supplier for specific fluid compatibility.Q: When should I consider using the Low Flow Glass Rotameter?

A: This rotameter is ideal when precise, real-time measurement of low flow rates is required, such as laboratory research, pilot plants, chemical dosing, or process monitoring where the measured range falls between 101000 LPH (liquid) and 0.110 Nm/hr (gas).Q: Where can the rotameter be used in the industry?

A: Due to its robust construction and flexible mounting options, it can be used in water treatment plants, chemical processing facilities, laboratories, and other industries requiring accurate low flow measurement and visual indication.Q: What is the measurement process and display type of this device?

A: The rotameter operates on a float-based visual flow measurement principle, providing a direct and immediate reading through the glass tube with finely graduated scale markings either engraved or printed for enhanced visibility.Q: How does the rotameter benefit my operation compared to other flow meters?

A: The key benefits include mechanical operation requiring no power supply, fine-scale accuracy (2% of full scale), easy visual monitoring, high chemical and pressure resistance, a variety of optional features, and flexibility in installation and customization.Q: What optional features are available for this rotameter?

A: Customers may request optional features such as alarm contacts for flow deviation alerts and integrated flow controllers for enhanced process control, tailored to specific application requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rotameters Category

Tube Rotameters

Price 8100 INR / Piece

Minimum Order Quantity : 1 , , Piece

Material : Borosilicate Glass Tube; Wetted Parts in SS 304/316, PTFE or PVC as per application

Accuracy : 2% of Full Scale

Display Type : Other, Analog (Direct Tube Reading)

Flow Rate : Directly Indicated on Tube Scale

Water Rotameter

Price 4500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Acrylic Body / Transparent Polycarbonate

Accuracy : 2% to 5% of Full Scale

Display Type : Other, Direct Tube Scale

Flow Rate : 10 to 40,000 LPH

Acrylic Body RotaMeter

Price 1260 INR / Piece

Minimum Order Quantity : 1 Piece

Material : High Quality Acrylic

Accuracy : 2% of Full Scale

Display Type : Other, Clear Acrylic Tube with Engraved Scale

Flow Rate : 10 to 20,000 LPH (liquids), 0.1 to 200 Nm/hr (gases)

By Pass Rotameters

Price 9000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : SS316/SS304/P.P.

|

FLOWTECH MEASURING INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry