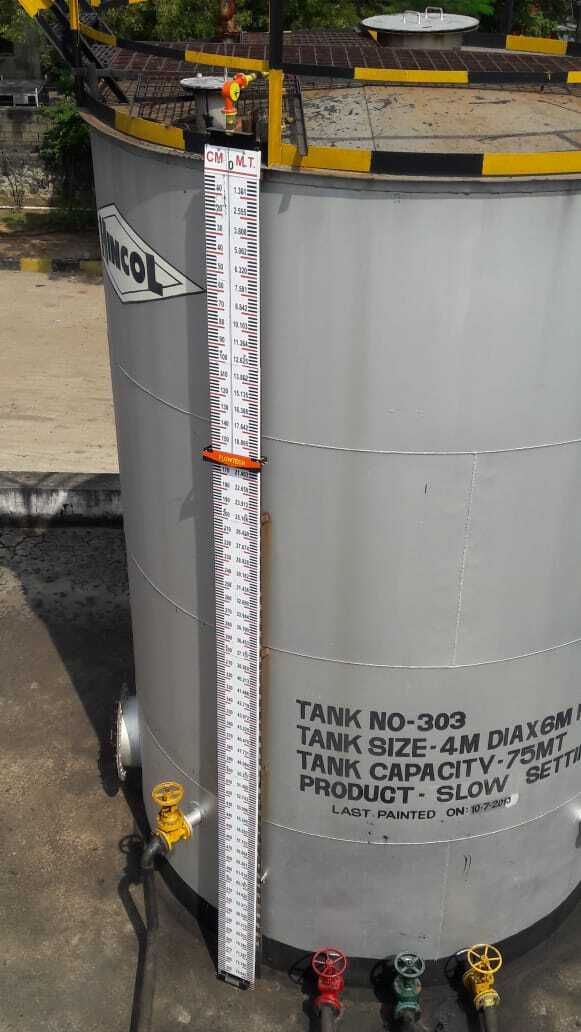

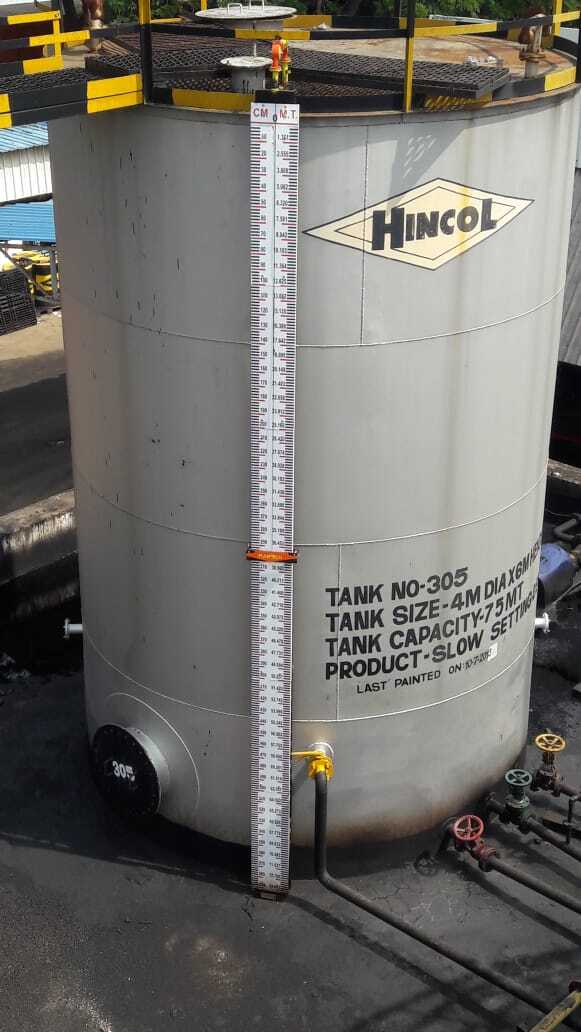

Float And Board Level Indicator

Price 8100 INR/ Piece

Float And Board Level Indicator Specification

- Pole Type

- Single

- Output

- Visual Level Indication

- Features

- Low maintenance, non-electrical operation, reliable

- Measuring Range

- Up to 15 meters (custom ranges available)

- Mounting Type

- Flange or Bracket Mounted

- IP Rating

- IP65

- Display

- Mechanical Board

- Usage & Applications

- Level measurement and indication in liquid tanks

- Installation Type

- Top-mounted

- Sensor Type

- Float Type

- Connectivity Type

- Mechanical Linkage

- Protection Level

- Weatherproof

- Product Type

- Float And Board Level Indicator

- Operating Temperature

- -10C to +65C

- Working Temperature

- Up to 65C

- Input

- Manual/Float Movement

- Pressure Type

- Atmospheric

- Diameter

- Float Diameter typically 120 mm

- Application

- Industrial tanks, water treatment plants, oil storage tanks

- Accuracy

- 10 mm

- Dimension (L*W*H)

- Customized as per tank size

- Weight

- Float Weight approx. 1.5 kg

- Indicator Board Material

- Aluminium/Stainless Steel

- Board Length

- Customizable to tank height

- Scale Graduation

- Marked in centimeters/meters

- Max. Liquid Density

- Up to 1.2 g/cm³

- Corrosion Resistance

- Yes

- Material of Float

- 304/316 Stainless Steel

- Float Shape

- Cylindrical or spherical

- Service

- Suitable for water, oil, chemicals

- Float Cable

- Stainless Steel Wire Rope

- Float Movement

- Counterweight & Pulley mechanism

- Maintenance

- Requires minimal maintenance

- Indication Range

- Full tank height

- Environmental Protection

- Suitable for outdoor installation

Float And Board Level Indicator Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 25 Pieces Per Week

- Delivery Time

- 1 Week

- Packaging Details

- As per requirement

- Main Domestic Market

- All India

About Float And Board Level Indicator

The Float & Board Level Indicator is a small and efficient instrument for monitoring liquid levels in tanks. It works on the buoyancy principle, with a float tied to a chain moving up and down to show the level. This straightforward yet powerful technique enables precise level measuring.

The Float & Board Level Indicator is intended for use in a variety of sectors, including as petroleum, pharmaceutical, and OEMs. It may be used to measure a wide range of liquid fluids, including acids, diluted alkalis, bases, and other chemicals often encountered in industrial applications.

FAQ-

What is the function of a vapour seal type float and board type level gauge?

The vapour seal type float and board type level gauge is widely used in tanks exposed to corrosive gases or vapours. It is also appropriate for nitrogen purging tanks.

How does the float and board type level gauge show the liquid level?

The float is connected to a magnetized counterweight that travels in a stainless steel conduit that is sealed. This action propels a follower magnetized two-colored capsule inside a glass tube, displaying the liquid level clearly.

Features-

- The Float & Board Type Level Gauge is made using high-quality materials including SS304, SS316, PP, PTFE, and others.

- This level gauge has a vapour seal design that makes it suited for tanks that are prone to corrosive gases, vapours, or nitrogen purging. It provides increased protection in hazardous conditions.

- For specialized applications involving chemicals such as HCl, diluted alkalis, N2 purged tanks, dilute HNO3, NH3, Benzene, Methanol, IPA, and others, the level gauge is supplied with magnetic vapour sealing.

- This particular device gives clear and exact liquid level readings for convenient monitoring.

Accurate and Reliable Level Measurement

This indicator provides dependable liquid level monitoring for industrial tanks. Its corrosion-resistant stainless steel construction and mechanical operation ensure performance in harsh environments. Installation is top-mounted, with customizable board lengths to match any tank height, making it suitable for water treatment plants, chemical processes, and oil storage facilities.

Designed for Durability and Low Maintenance

Manufactured with quality materials, including 304/316 stainless steel floats and an aluminium or stainless steel board, this device delivers years of operation with little upkeep. The robust design is weatherproof and IP65 rated, enabling outdoor use and resistance to environmental conditions.

Flexible Application and Easy Customization

The Float and Board Level Indicator can be configured for tanks up to 15 meters high. With options for cylindrical or spherical floats and graduated scales, it fits a range of liquid densities and tank sizes. Mounting is straightforward using bracket or flange fittings, and dimensions can be tailored for every project.

FAQs of Float And Board Level Indicator:

Q: How does the Float and Board Level Indicator operate without electricity?

A: This indicator uses a mechanical linkage system, where a stainless steel float activates a pulley and counterweight mechanism. The movement of the float is visually displayed on a graduated board, offering reliable readings without electrical inputs, making it ideal for remote or hazardous installations.Q: What types of liquids can this level indicator measure?

A: It is suitable for water, oil, and a variety of chemicals, provided the liquid density is up to 1.2 g/cm. The devices construction resists corrosion, allowing it to perform in diverse industrial environments without compromising precision.Q: Where should the Float and Board Level Indicator be installed for optimal performance?

A: This instrument is designed for top-mounted installation on industrial tanks. It is weatherproof and IP65 rated, which makes it suitable for both indoor and outdoor environments, including water treatment facilities and oil storage tanks.Q: What is the process for customizing the indicator to fit specific tank sizes?

A: Customization is available for board length, float shape, and overall dimensions. By providing tank specifications, manufacturers can tailor the indicator to ensure accurate measurement across the full height of the tank, up to 15 meters.Q: What are the benefits of using a mechanical float level indicator versus electronic alternatives?

A: Mechanical indicators offer low maintenance, high reliability, and operate independently of power supply. They are less susceptible to electrical faults, perform consistently in extreme weather, and simplify visual tank monitoring.Q: How often does the Float and Board Level Indicator require maintenance?

A: The unit is engineered for minimal upkeep, thanks to its robust stainless steel and aluminium construction. Periodic inspections are recommended, but routine maintenance needs are significantly lower than electronic systems.Q: What is the typical accuracy and measuring range of this indicator?

A: The float device provides an accuracy of 10 mm and can measure tank levels up to 15 meters. The scale is marked in centimeters or meters, ensuring granular and precise liquid level indication for operational safety and inventory management.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Level Indicator Category

Side Mounted Magnetic Capsule Design Level Indicator

Price Range 5000.00 - 12600.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Liquid Level Measurement in Tanks and Vessels

Pressure Type : Hydrostatic

Working Temperature : 100 Celsius (oC)

Bicolor Roller Type Level Indicator

Price 8100 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Water,Chemical

Pressure Type : 15

Working Temperature : 150 Celsius (oC)

Fuel Tank level indicators

Price 6300 INR / Piece

Minimum Order Quantity : 1 Piece

Application : WATER, BOREWELL WATER, CEMICAL, ALCOHOL

Working Temperature : 100 Celsius (oC)

Level Indicator

Price Range 4000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Application : Water,Liquid

Pressure Type : 10 kg/cm2

Working Temperature : 100 Celsius (oC)

|

FLOWTECH MEASURING INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry