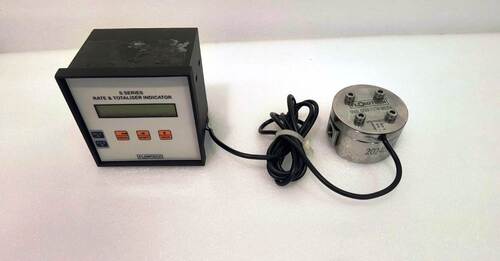

Oval Gear Flow Sensor

Price 18000 INR/ Number

MOQ : 1 Number

Oval Gear Flow Sensor Specification

- Connectivity Type

- Pulse and 4-20mA output

- Frequency

- Pulse output up to 1kHz

- Temperature Range

- -20 to 80C

- Flow Rate

- 10 to 5000 L/h

- Protection

- IP65

- Resolution

- 0.01 L/h

- Diameter

- 15 mm (DN15)

- Sensor Type

- Positive displacement, oval gear

- Application Media

- Liquids (e.g. water, oils, chemicals)

- Measurement Range

- 10~5000 L/h

- Capacity

- Varies by model

- Humidity %

- 0-95% RH non-condensing

- Current Range

- 4-20mA

- Pressure Range

- Up to 1.6 MPa

- Material

- Aluminum alloy body

- Power Supply

- 24V DC

- Power Consumption

- < 2W

- Accuracy

- 0.5% of reading

- Display Type

- Digital LCD

- Range

- 10 to 5000 L/h

- Operating Pressure

- Max 1.6 MPa

- Cable Gland

- M20x1.5

- Weight

- Approximately 1.5 kg

- Viscosity Range

- 2 to 1000 mPa·s

- Repeatability

- ±0.2%

- Power Indicator

- LED

- Equipment Type

- Oval Gear Flow Sensor

- Output Signal

- Pulse, 4-20mA, optional RS485

- Mounting Method

- Flanged or threaded

- Installation

- Horizontal or vertical

Oval Gear Flow Sensor Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- Vadodara

- Payment Terms

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C)

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Week

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- Wooden Cages

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Oval Gear Flow Sensor

Technical Data SheetMaterial of construction :

Enclosure: Aluminum anodize/S.S-304/S.S-316

Rotor: Aluminum anodize/S.S-316/PPS

O-ring: NBR/Viton

Shaft: Hard Stainless Steel-316 Accuracy (standard installation position) : 1% RS /0.15% FSD Repeatability : 0.1%.

Maximum working pressure: 5 MPa for aluminum body, 25 MPa for S.S body, above 250 bars please Contact Company.

Fluid & Ambient temperature: -40 to 80C

Power voltage: Battery operated

Connection: Thread (M/F) or Flange.

Connection Size : 1/4" to 3"

Flow Range : 50 LPH TO 50000 LPH

Application :

Aluminum body and rotor: Flow measurements of kerosene, Gasoline, diesel, light oil, heavy oils. Body and rotor: Flow measurements of Pharmaceutical drug, food oil, and all application.

Calibration process :

*Calibrated each flow sensor with three pressure point : 0.5,4 and 25 bar,

*All pressure calculate pulse/litter at : 25%, 50%, 75% and 100% flow rate

*Calibrated with pure diesel.

1) Pulse Output Sensor :

Power voltage: 12 V DC

Output signal: NPN open connector

Output: High electric level: High than 8 VDC (input voltage 12 VDC) Low electric level: lower than 0.8 VDC (input voltage 12 VDC)

3) Display with 4 to 20 mA

Output Power voltage: 24 V DC Output signal: 4 TO 20 mA

Precision Measurement with Advanced Output Options

This oval gear flow sensor delivers reliable and accurate flow measurement for liquids across various industries. With a repeatability of 0.2%, advanced digital outputs (pulse, 4-20mA, and RS485), and a wide viscosity range (2 to 1000 mPas), it excels in diverse process conditions. Designed with both flanged and threaded mounting, it is straightforward to fit into new or existing pipelines, ensuring seamless integration and dependable performance.

Rugged Design for Demanding Environments

Built with an aluminum alloy body and an IP65 protection rating, the sensor is resistant to dust and water ingress, making it suitable for challenging industrial applications. The digital LCD display and LED power indicator provide clear, real-time data at a glance. With a wide operating temperature range (-20 to 80C) and a maximum pressure capability of 1.6 MPa, this flow sensor ensures longevity and consistent operation under harsh conditions.

FAQ's of Oval Gear Flow Sensor:

Q: How should the oval gear flow sensor be installed for optimal performance?

A: The sensor can be installed in either a horizontal or vertical orientation, depending on the pipeline layout. It supports both flanged and threaded mounting, providing versatility for integration into existing systems. Proper alignment and secure fitting are essential to ensure accurate measurements and prevent leaks.Q: What liquids are suitable for measurement with this sensor?

A: This oval gear flow sensor is designed to measure a wide variety of liquids, including water, oils, and chemicals, within a viscosity range of 2 to 1000 mPas. Its robust design and precision components make it suitable for use in industrial, chemical, and process applications.Q: When is it beneficial to use an oval gear flow sensor over other types?

A: Oval gear flow sensors offer superior accuracy and repeatability, making them ideal when precise flow measurement is critical, such as in batch processing or dosing applications. They perform especially well with viscous liquids and provide reliable results under fluctuating pressure and flow conditions.Q: Where can this sensor be installed and what environment is it best suited for?

A: With an IP65 protection rating, the sensor is suitable for installation in environments exposed to dust or occasional water sprays. Its temperature range (-20 to 80C) and resistance to humidity (0-95% RH, non-condensing) make it ideal for factories, processing plants, and chemical facilities across India.Q: What is the process for connecting the sensor to a monitoring system?

A: The sensor offers multiple output options: pulse, 4-20mA analog signals, and optional RS485 communication. These outputs enable seamless integration with PLCs, data acquisition systems, or control panels. The M20x1.5 cable gland ensures secure and safe cable entry during installation.Q: How can users benefit from the sensor's digital display and power indicator?

A: The clear digital LCD provides instant flow readings, while the LED indicator allows users to quickly confirm the power status. This combination minimizes troubleshooting time and supports efficient on-site monitoring and maintenance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Oval Gear Flow Meter Category

Digital Diesel Flow Meter Oval Gear Type

Price 18000 INR / Number

Minimum Order Quantity : 1 Number

Display Type : Analog And Digital

Usage : Diesel / Oil

Product Type : Oval Gear Type Flow Meter

Oval Gear Oil Flow Meters

Price 15200.0 INR / Piece

Minimum Order Quantity : 1 Number

Display Type : Digital Only

Usage : Testing & Measurement

Product Type : Gear Oil Flow Meters

Material : Metal

Digital Oval Gear Flow Meter

Price 18000 INR / Number

Minimum Order Quantity : 1 Number

Display Type : Digital Only

Usage : Industrial

Product Type : Digital Oval Gear Flow Meter

Material : MS

|

FLOWTECH MEASURING INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry