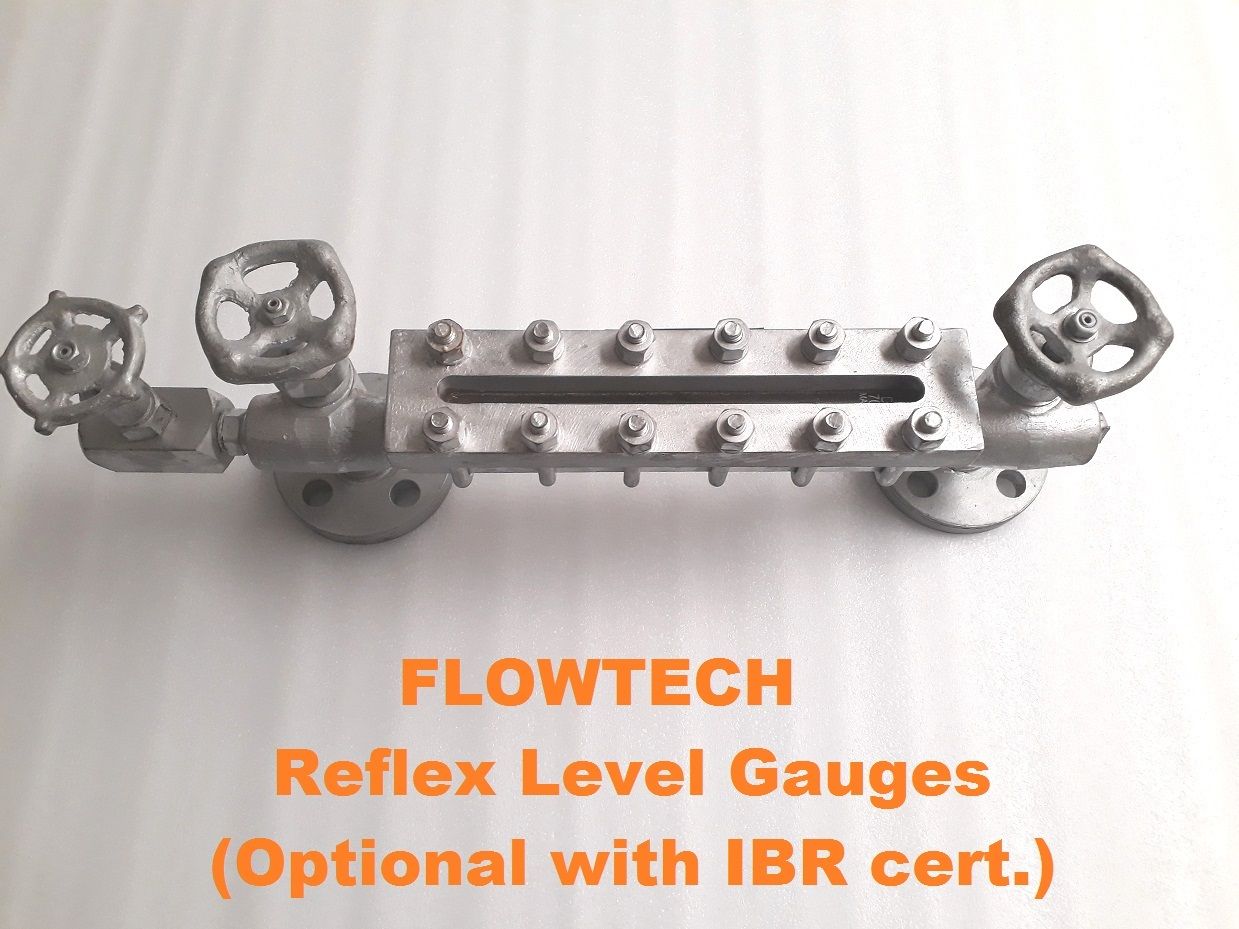

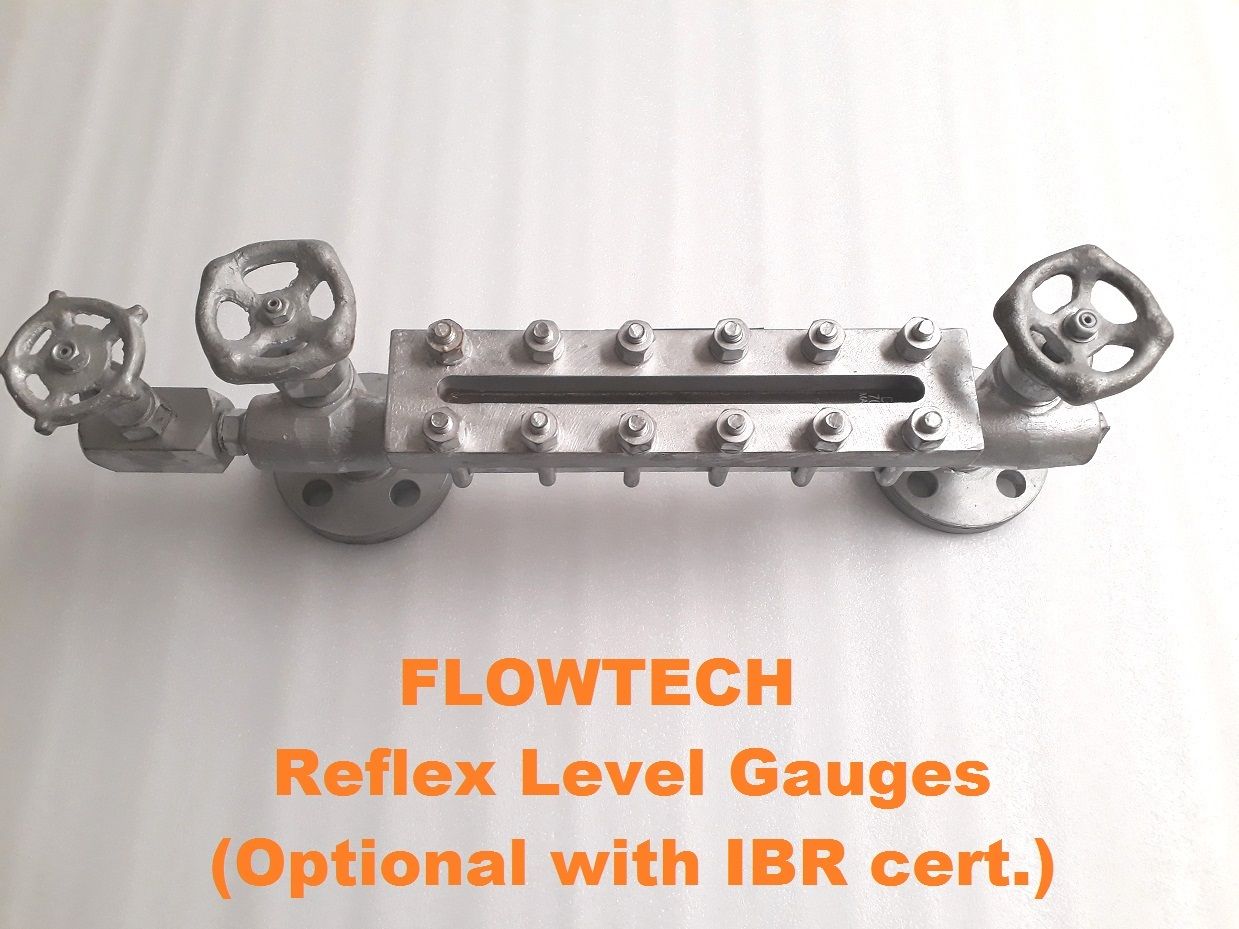

Boiler Steam IBR Level Gauge

Price 8100 INR/ Number

MOQ : 1 Number

Boiler Steam IBR Level Gauge Specification

- Usage

- Steam

- Size

- 20 NB

- Product Type

- IBR Level Gauge

- Weight

- 12 Kilograms (kg)

- Application

- Oil Refineries, Marine Engineering, Food And Beverages Industry, Textile Industry, Petro Chemical Plants, Pharmaceutical Manufacture, Chemical Processing, Mechanical Engineering, Water Engineering, Pulp And Paper Industry, Nuclear Power Engineering

- Color

- Silver

- Length

- 400 Millimeter (mm)

- Accuracy

- 0.5 %

Boiler Steam IBR Level Gauge Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- Vadodara

- Payment Terms

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C)

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Boiler Steam IBR Level Gauge

The product is designed for safe and positive visual indication of liquid level in vessels under high pressure & temperature conditions. These gauges have a prism glass window that uses the basic optical principles of light refraction & reflection to enhance the indication of the liquid level. It is a flat glass gauge, which has precision moulded prismatic grooves cut on its inner side, which comes in contact with the medium. Light striking the glass covered by liquid is refracted (absorbed) into the liquid making this portion appear black, whereas light covering the vapour space is reflected back towards the viewer, making it appear silvery-white. Thus, a sharp clear line marks the liquid level.

Reflex Level Gauge: The liquid chamber is formed by one-piece metal body, reflex gauge glass, sealing gasket, cushion and cover plate all held together by U-bolts and nuts.

Transparent Level Gauge: The construction is similar to Reflex except that the liquid chamber is formed by one-piece metal body and a pair of transparent gauge glass plate.

Product Specification:

Gauge Classification : Standard Chamber

Gauge Glass : Klinger / Maxos Make Tempered borosilicate (Imported) in 30mm width as standard.

Cushion : SS with Graphite

Gasket : SS with Graphite

Body (Liquid Chamber) : CS A-105 (ASTM A-105)

Cover Plate : CS (ASTM A-105)

Bolts and Nuts : EN-8

CC Distance : 300, 320,350, 385, 400, 450, 500,600,750,800,850 MM

Gauge Connection : Straight Through / Hook -Up

Process Connection : Flanged to BS, ANSI or DIN

Orientation of PC : Side Mounted at Top/Bottom

Isolating valves : Integral Offset Needle Valve

Air Vent : Plug (CS A-105)

Drain : Globe/Needle valve

Max.Test Pressure : 0-70 Kg/cm

Max. Temperature (C) : 0-450C

Product Features :

1. Long service life

2. Easy installation

3. Tempered Borosilicate Glass, resistant to chemicals, thermal & mechanical shock

4. The offset designed isolation valve allows easy cleaning of the gauge body without removing the same from the boiler.

Reflex Level Gauge: The liquid chamber is formed by one-piece metal body, reflex gauge glass, sealing gasket, cushion and cover plate all held together by U-bolts and nuts.

Transparent Level Gauge: The construction is similar to Reflex except that the liquid chamber is formed by one-piece metal body and a pair of transparent gauge glass plate.

Product Specification:

Gauge Classification : Standard Chamber

Gauge Glass : Klinger / Maxos Make Tempered borosilicate (Imported) in 30mm width as standard.

Cushion : SS with Graphite

Gasket : SS with Graphite

Body (Liquid Chamber) : CS A-105 (ASTM A-105)

Cover Plate : CS (ASTM A-105)

Bolts and Nuts : EN-8

CC Distance : 300, 320,350, 385, 400, 450, 500,600,750,800,850 MM

Gauge Connection : Straight Through / Hook -Up

Process Connection : Flanged to BS, ANSI or DIN

Orientation of PC : Side Mounted at Top/Bottom

Isolating valves : Integral Offset Needle Valve

Air Vent : Plug (CS A-105)

Drain : Globe/Needle valve

Max.Test Pressure : 0-70 Kg/cm

Max. Temperature (C) : 0-450C

Product Features :

1. Long service life

2. Easy installation

3. Tempered Borosilicate Glass, resistant to chemicals, thermal & mechanical shock

4. The offset designed isolation valve allows easy cleaning of the gauge body without removing the same from the boiler.

FAQs of Boiler Steam IBR Level Gauge:

Q: What is the accuracy of the Boiler Steam IBR Level Gauge?

A: The accuracy of the gauge is 0.5%.Q: What industries can this gauge be used in?

A: This gauge can be used in a variety of industries, including oil refineries, marine engineering, food and beverages, textile, petrochemical plants, pharmaceuticals, chemical processing, mechanical engineering, water engineering, pulp and paper, and nuclear power engineering.Q: What is the size of the gauge?

A: The gauge has a size of 20 NB and a length of 400 millimeters.Q: What is the weight of the Boiler Steam IBR Level Gauge?

A: The gauge has a weight of 12 kilograms.Q: What color does the Boiler Steam IBR Level Gauge come in?

A: The gauge comes in a sleek silver color that will complement any industrial setting.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Reflex Level Gauge Category

IBR Reflex Level Gauges

Price 8550.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : IBR Level gauge

Color : Silver

Application : Oil Refineries, Marine Engineering, Textile Industry, Petro Chemical Plants, Pharmaceutical Manufacture, Chemical Processing, Mechanical Engineering, Water Engineering

|

FLOWTECH MEASURING INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry